After the joyful Christmas days, the end of the year is nearby. 2022 Was a fruitful year, with once again record-breaking sales results. We have been able to pick up traveling again and deliver more bond testers worldwide than ever before. So, we are excited for 2023 – how about you?

In this newsletter, you can read about the expected novelties. We will launch a new software version with many improvements and new (automation) functionalities. We have worked hard to make our systems compatible with GEM300 for automatic lead frame and water testing. Other product launches planned for the new year are kept secret for now. Our engineers work with prestigious customers on several projects, pushing bond testing technology forward.

New cameras

All Sigma bond testing systems have new cameras for faster automatic bond testing. The downward-looking, side view, and trinocular camera have better-embedded functionalities to make the systems much faster for fully automated bond testing.

GEM300

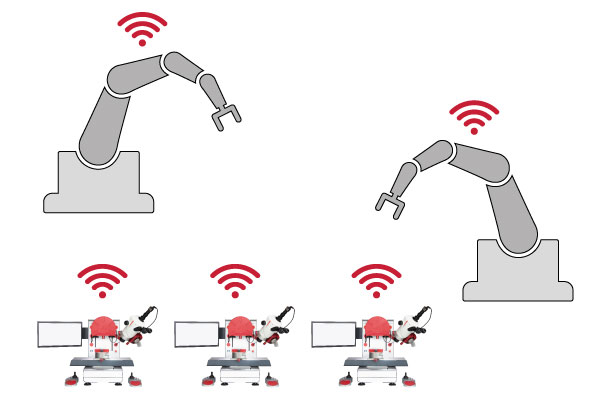

The semiconductor industry is moving towards entire factory automation, and a fourth industrial revolution is taking place, industry 4.0. Industry 4.0 refers to the intelligent networking of machines and processes with the help of information and communication technology.

Especially for automatic lead frame testing, we implement GEM300, our hardware, and new 5.17 software to be compatible with an industry-wide group of SEMI standards and to “speak” the same language as all systems semiconductor factories. Additionally, we can also use it for automating wafer testing.

GEM300 consists of the following:

Carrier management (SEMI E84 + E87)

Manages the material’s delivery, handling, and validation by handing off carriers by an Automated Material Handling System (AMHS) or Overhead Hoist Transfer (OHT). Substrates are accessible for processing after validations of the carrier. The bond tester validates the ID and Slot map by means of readers and slot map sensors.

Substrate tracking (SEMI E90)

Tracks all substrate movement inside the equipment, The substrate ID can be verified because the equipment contains a reader.

Process Job and Control Job (SEMI E40+ E94)

Process Jobs contains a list of materials and the name of recipes for the process. A Control Job manages a set of Process Jobs.

Equipment Performance tracking (SEMI E116)

Measures and analyzes equipment performance for preventive and predictive maintenance to reduce downtimes and anticipate root causes of alarms.

Software release 5.17 is coming soon

We are constantly developing our software. Soon we will launch version 5.17, with some touches of our new brand identity. This version contains many improvements over the 5.16 version. It comes with new functionalities such as GEM300, support for new camera systems, the possibility to use optical character recognition (OCR), a new test functionality Loop height measurement with PID, and support for our auto-adjustable strip work holder.

There are also new functionalities to better the user experience for programming automations and automatic grading. In addition, we have improved the software’s speed, export functionalities, and memory usage.

We will cover other new functionalities, and changes in future newsletters after the 5.17 software is released. Stay tuned!

Cheers to the New Year

We hope you had a wonderful Christmas! As we reflect on the past year, we want to acknowledge those who helped us shape our business. The technology evolves, and we feel grateful for believing in us to develop custom solutions for your bond testing requirements.

Thanks for a great year, and we wish you peace, joy, and prosperity throughout the coming year.

Happy and Prosperous 2023!

No limitations

As the technology leader, we take on the latest challenges in bond testing and anticipate future market demands. At xyztec, our team has the experience and expertise to create custom bond testing solutions to fulfill all test requirements. Do you have a challenge for us? Please contact us.