In the ever-evolving world of electronic and semiconductor manufacturing, the importance of testing the mechanical strength of bonds cannot be underestimated. In this newsletter, we explain why this aspect of the production process is so crucial and how it directly impacts product success, customer satisfaction, and overall profitability.

Why Test Bonds?

Bondtesting is crucial to minimize system breakdowns. Electrical or thermal bonds are the backbone of electronic and semiconductor constructions. A single failed bond in a product, such as a laptop, may lead to a catastrophic system breakdown. Understanding and ensuring the strength of these bonds is essential for the reliability and longevity of the final product and satisfied customers.

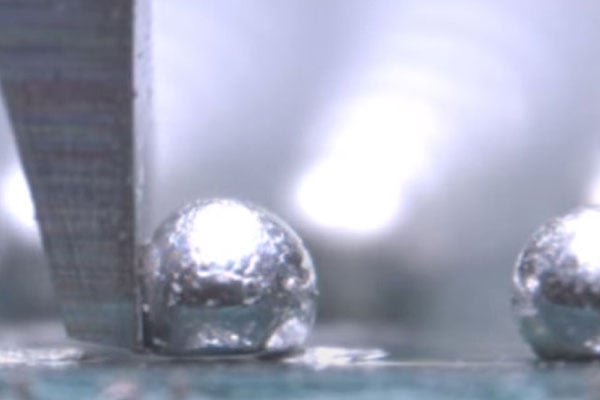

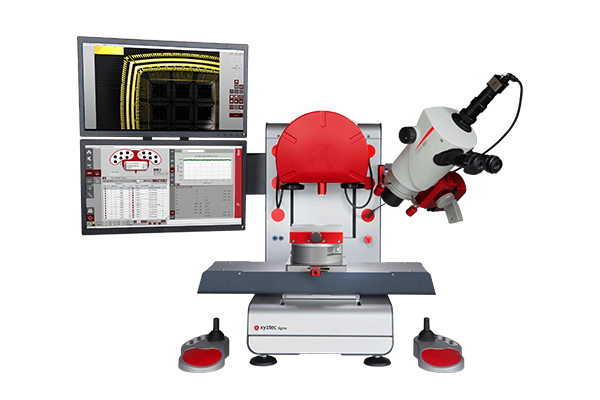

Our cutting-edge Sigma bond test systems accurately test various applications, from bond wires to solder bumps, dies, leads, chips, and lids, with strengths ranging from a few grams to hundreds of kilograms of force.

Why measure bond strength?

Bonds can fail during production or end use due to factors such as geometry, material, or processing issues. These failures significantly impact the quality and integrity of the bond. Measuring bond strength becomes valuable during the design process and for quality control, minimizing product variability and increasing end-product reliability.

Types of bond testing

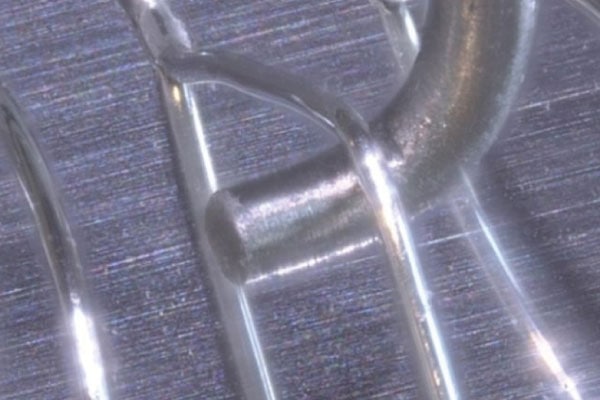

In bond testing, there are two main types: pull and shear testing. Both test types are most often destructive to the sample, but there is a non-destructive alternative, commonly used in critical applications like military or aerospace, ensuring extreme reliability.

Pull testing

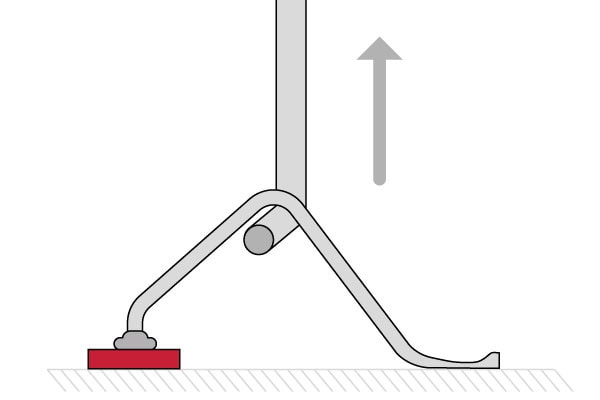

Pull Testing applies an upward force from underneath gold, aluminum, or copper bonded wires, causing the wire to be pulled away from the substrate until the bond breaks (destructive) or a pre-defined force is reached. This test provides valuable data on bond strength and failure modes, which are essential for evaluating the quality of the bond.

Shear testing

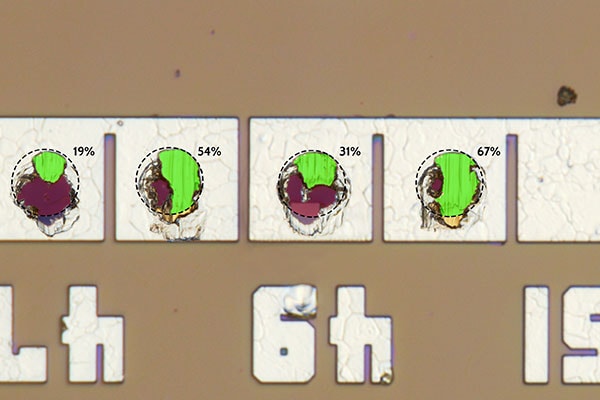

Shear testing involves applying force to determine the strength of adhesion between the bond and it surface. This method is particularly effective for measuring the strength of balls, glue, solder, and sintered silver bonds.

The choice between pull or shear testing depends on the application and the test objectives. There are numerous ways to test applications. Click to learn more about various types of test methods.

How to test bonds?

As forerunners in bond testing, we aim to spread knowledge about bond testing in the industry. We offer how-to’s on Wire Pull (WP), Shear, Cold Bump Pull (CBP), and Tweezer Pull (TP) and access to the relevant MIL-STD-883 standards.

Feel free to use these guides to bond testing. Please reach out if you have any comments or specific questions regarding the application or your samples.

Measure the mechanical strength of bonds

In conclusion, bond testing may be a nuanced and varied subject, but its contribution to ensuring product quality is undeniable. Precise force-displacement measurement using a modern bond tester allows for modeling that predicts failure modes accurately, serving as a reliable model for real-life loading conditions.

At xyztec, we are committed to providing the latest insights and innovations in the electronic and semiconductor industries. Sigma bond testers are a revolutionary solution for measuring mechanical bond strength. The Sigma bond tester outshines all other bond testers with a remarkable 0.075% accuracy and a relative shear height precision of 200 nm. Choose a Sigma and enjoy game-changing automation capabilities, including hands-free (un)loading and deep learning image processing for automatic testing and analysis.

Get your free SMT ticket!

Xyztec is exhibiting at the SMTconnect 2024 in Germany from 11-13th June, and we invite you to our booth Hall 4A – Booth 102. Get your free SMT ticket by sending a short e-mail including your full name, telephone number, and company name. You will receive the corresponding code from us to register for the SMTconnect.