Wire pull

Wire Pull Testing applies an upward force under the wire, effectively pulling it away from the substrate. There are many types of pull tests, therefore xyztec offers a solution for each type. The pull test can be performed on wires or ribbons. The material of the wires or ribbons is mostly gold, aluminum or copper.

The majority of tests on wire bonds are performed with a 90° hook that is positioned under the wire. The Z-stage then moves up and the wire is pulled. The alignment of the hook under the wire is very important to obtain reproducible measurements. This can be ensured using our semi-automatic or fully automatic testing compliant with DVS2811.

How to: Wire pull

We aim to spread knowledge about bond testing in the industry. That is why we have an extensive “how-to” on Wire Pull on our website.

Thin wire pull

Media error: Format(s) not supported or source(s) not found

下載檔案: https://xyztecvideos.b-cdn.net/Wire%20pull%20test%20-%20thin%20wire.mp4?_=1

Thick wire pull

Media error: Format(s) not supported or source(s) not found

下載檔案: https://xyztecvideos.b-cdn.net/Wire%20pull%20test%20-%20thick%20wire.mp4?_=2Standards

- MIL-STD-883 method 2011.9 bond strength (destructive bond pull test)

- MIL-STD-883 method 2023.7 nondestructive bond pull

Test features

- Sensor accuracy ±0.075%

- Rotational accuracy ±0.05°

- Destructive and nondestructive testing

- Pull angle modeling is also available with DVS2811 software

- Possible to combine with loop height test

- Automatic wire detect

Automatic wire detection

On many applications, the placement of wires is inconsistent, and easy automation programs will miss the wire or pull two wires at once. The high-resolution cameras on a Sigma bond tester, combined with advanced wire detect algorithms, make it possible to correct for production tolerances for every single wire, even in fine pitch bonding scenarios.

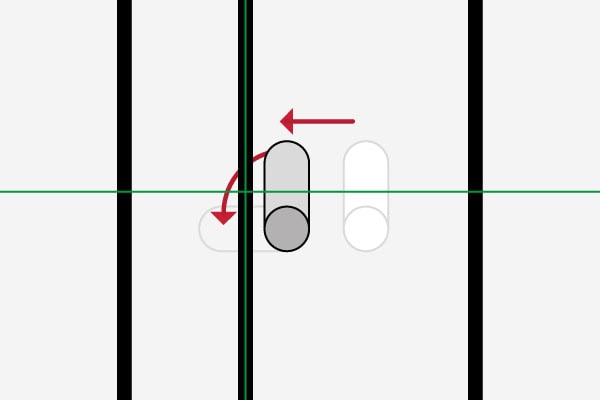

At the location of the green crosshairs, the illustration shows how the hook is driven to a corrected position after the bond tester detects the wire. When the bond tester performs the pull test, it does not miss the wire but pulls it in the same position as every other wire.

Automatic wire detection enables a higher degree of consistency over what is possible when testing manually.