Did you know that it is really easy to test the quality of your coatings using a Sigma bond tester? You do not need to purchase a detached scratch tester. Our Sigma bond testers are highly flexible and offer a wide range of capabilities, including scratch and coating testing.

Fully automated scratch testing

Maintaining high-quality coatings, paints, and films is essential in the semiconductor industry. Scratch testing is an effective test method to measure the quality of the adhesive bond of single or multiple coatings to the substrate and/or each other. A Sigma bond tester can perform a complex coating scratch test fully automatically with increased throughput by several orders of magnitude.

The fully automatic mode delivers even more benefits, allowing easy sample loading and testing. Sigma bondtesters have fiducial mark pattern recognition to locate the samples’ position and then test with precision with whatever combination of scratch tests you want. These can be different positions, procedures, directions, and speeds.

How to scratch test?

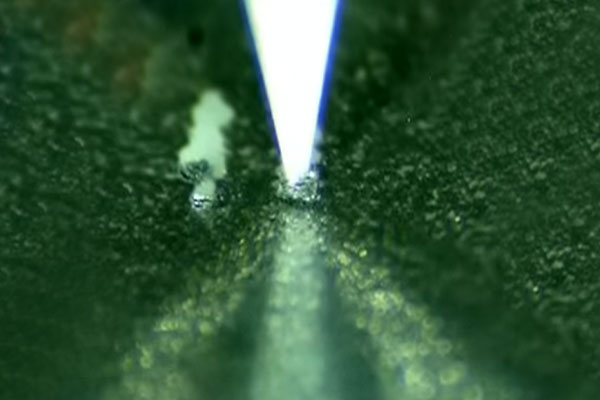

Utilizing a special shear tool or a diamond Nano Indenter tip makes it possible to land on a coating or multiple coatings and then scratch along the surface with increasing load. At a critical force, the substrate either experiences delamination from the coating or the tool cuts through to the substrate. Precision XY stages ensure the reliability of the testing process.

This method evaluates adhesion by compressing both the coating and the underlying material while creating the scratch. If the underlying material possesses lower yield strength, the coating stretches over the valley formed in the bulk material, resulting in delamination. Conversely, if the underlying material has higher yield strength, the coating is squashed against it, expanding and eventually delaminating in the x and y directions. Unlike tensile tests, scratch tests provide a more realistic assessment of coating materials, effectively comparing material combinations and processes.

Programmable landing force

The programmable landing force enables control of the scratch force and synchronous measurement together with the horizontal shear force for scratch testing. Weak bonds can be identified by the failure mode of delamination and the force-displacement graph of the scratch tool.

Scratch testing procedure

There are 3 standard procedures for scratch testing:

- Progressive Load Scratch Test (PLST)

- Constant Load Scratch Test (CLST)

- Multipass Scratch Test (MPST)

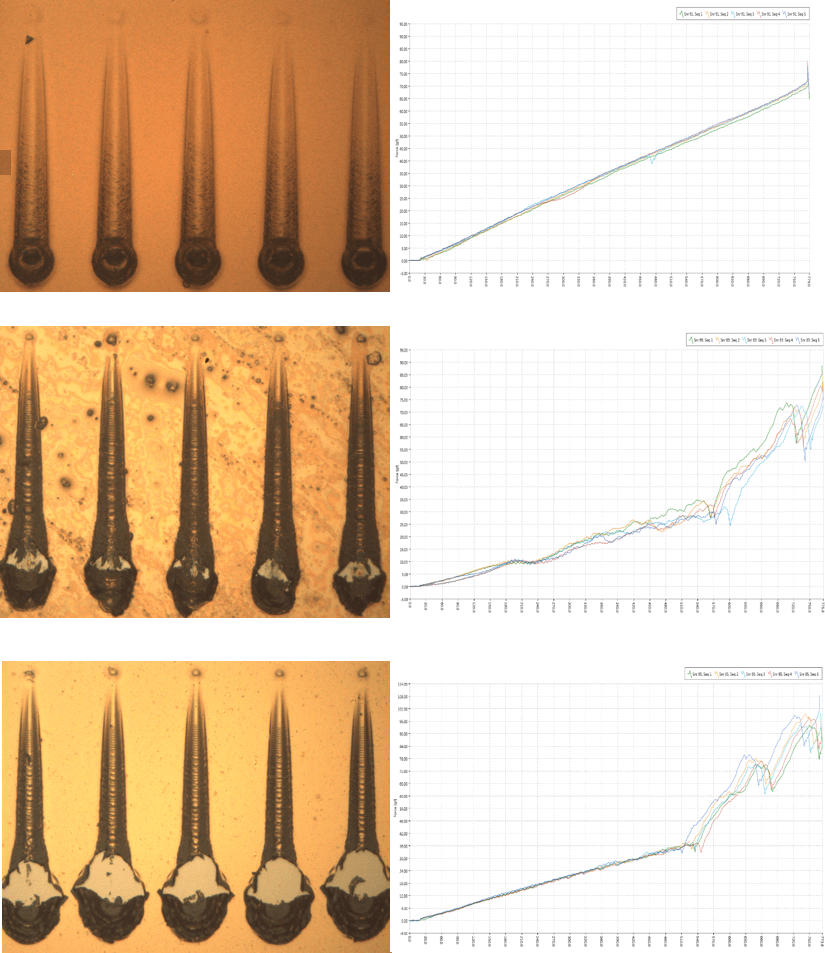

As with any scratch tester, the bond quality between layers can be seen in the failure mode and force displacement graph. The following examples show the same PLST on multi-layer films of different constructions.

Additional failure mode analysis such as EDX helps to show at what point layers fail. With this deeper understanding quality assurance may subsequently only require scratch testing.

Sigma bond testers

Experience the power of scratch testing with a Sigma bond tester. It is a highly flexible micromaterials tester specifically for the semiconductor and electronics industry. It was designed for comfortable and easy manual use from its inception, making it significantly faster than dedicated scratch testers. Being automatic, every sample is tested exactly the same way, saving time and effort.

So, what are you waiting for? Forget about detached scratch testers and choose a flexible advanced bond tester to measure the quality of your coatings. If you already own a Sigma bondtester, you need a special tool, and you are ready to test your coatings.

Contact us to learn more about our scratch testing solutions.