We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

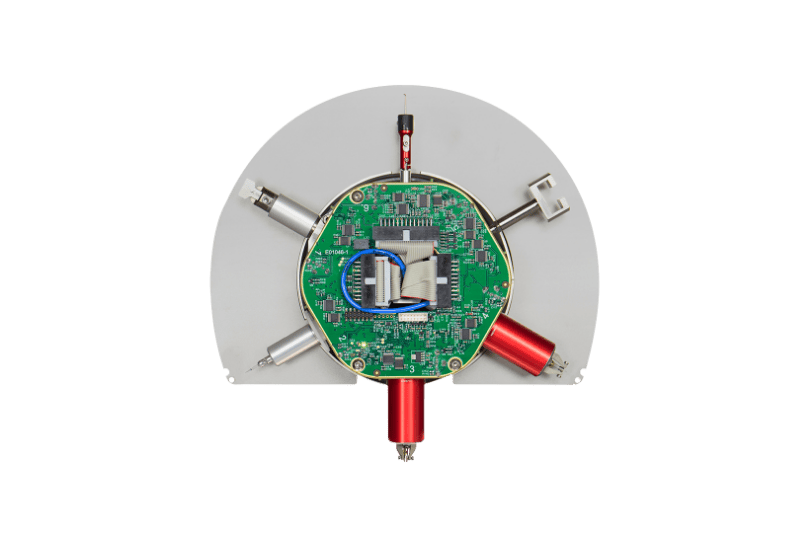

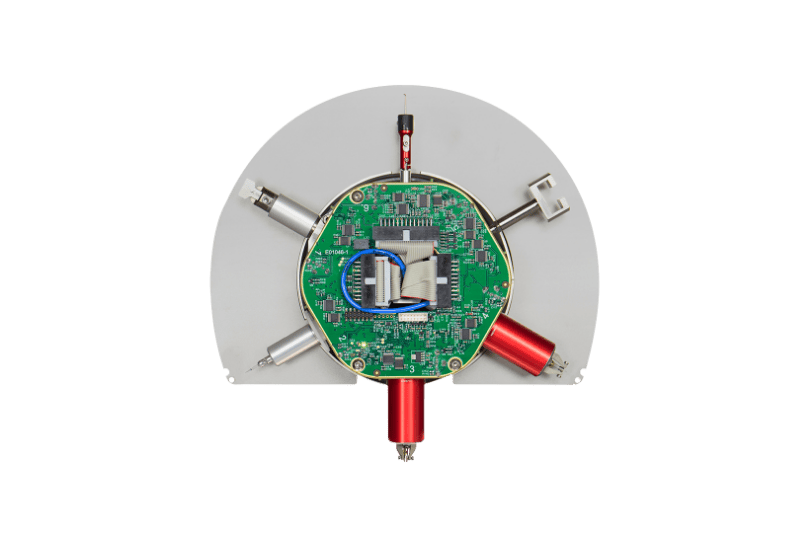

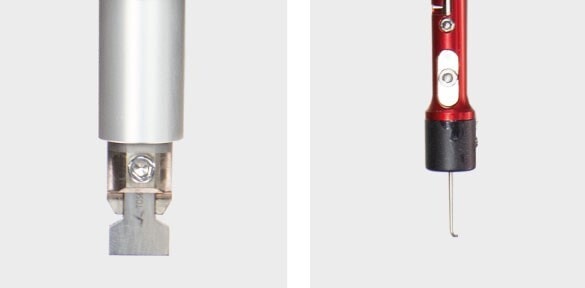

Sigma 焊點測試機的模組化設計,具備改變遊戲規則的自動化能力,自動取片與放片, 自動測試和結果分析, 可旋轉測試模組(RMU)最多可搭載6個感測器以滿足連續性的測試,軟體包括視覺和深度學習技術可免除人為因素錯誤。

Sigma W8 和獨立的晶圓傳送機整合,以達到全自動傳送晶圓, 自動從原片盒中取片後,自動對位並放置在測試機載台上進行測試。

此系統透過PID控制晶圓頂桿, 頂桿上的柔軟、具彈性的吸盤, 輕柔地固定平整或翹曲的晶圓。

Sigma W8可升級為市場領先的Sigma W12測試機,可全自動測試12英寸(300mm)的晶圓。 Sigma W12配有600mm 的X 軸,最小可測試20μm晶粒。 這種升級可能, 確保Sigma W8成為一台永不過時的產品。

消除人為錯誤並節省生產成本。

機器人處理可確保應用程式的安全裝載和卸載,並避免處理錯誤和損壞。我們提供以下處理程序:

開放式 Sigma 軟體可輕鬆對整個自動化步驟、位置和指令進行程式設計。自動化編輯器採用相機視覺化和智慧嚮導。

透過多達 3 個即時相機選項查看看不見的事物。使用高解析度相機、靈活的 LED 照明和出色的影像處理選項,透過影像或視訊展現感興趣的特徵。

精確的工具對準對於正確測試正確的黏合至關重要。我們提供多種完美對齊解決方案:

將可識別的形狀、圖案或標記定義為定位和自動工具對齊的全局或局部參考。

辨識因製程公差或零件處理而錯位的元件和細間距電線。

Sigma 提供2 種替代方案,使分級更加高效和一致:

在分級輔助下自動對測試結果影像的故障模式進行分級。光學檢查計算剩餘散裝材料面積佔整體的百分比。

詳細的光學檢查可協助您執行影像測量或識別捕獲的測試結果的故障模式。對於更高級的影像處理、濾鏡、分割和形狀檢測,您可以使用自動光學檢測 (AOI)。

使用自動匯出和 SECS/GEM 進行追蹤和控制來改進資料處理。

| STAGES | SIGMA W8 |

|---|---|

| X-stage (mm) | 370 |

| Y-stage (mm) | 370 |

| Z-stage (mm) | 168 |

| Axis speed (mm/s) | 50 |

| Resolution linear encoders (backlash free drives) (nm) | 30 |

| Digital temperature correction | |

| ACCURACY | |

| Accuracy (%) | 0.075 |

| ADC resolution (bit) | 24 |

| Sampling frequency (kHz) | 10 |

| Shear height (step back) accuracy ±1 μm | |

| Programmable landing force down to 5 gf | |

| MECHANICAL | |

| Footprint X (mm) | 620 |

| Footprint Y (mm) | 935 |

| Height (mm) | 608 |

| Weight (± kg) | 100 |

針對貴公司的需求,請聯絡我們以取得更多的資訊和選配. 規格如有任何變動, 請恕無法即時通知.

![]() 標準

標準

![]() 選配

選配

![]() 不適用

不適用

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

開發世界一流的結合力測試技術,並與全球合作夥伴一起在全世界提供當地服務支援。

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands