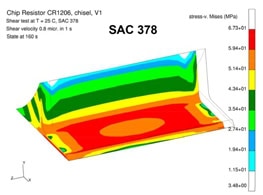

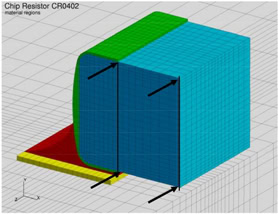

SMD component shear

While 100 μm is currently a commonly used line width for printed circuit boards in the near future, this is expected to become as low as 20 μm. Reductions in the linear scale are not linear when it comes to other aspects of board design like solder interconnects. For example, such a reduction in scale reduces solder volumes by around 50 times.

On the other hand the intermetallic layer thickness will not be reduced, resulting in a dramatic change in the distribution of material properties within the joint and the changes within it due to aging and/or electro migration. Similarly, surface irregularities become larger in comparison to the solder pads changing the geometry of the soldered joint and its consistency. At smaller scales stress concentration becomes more likely, increasing the risk of crack formation and them propagating through the relatively large intermetallics.

How to: SMD component shear

Media error: Format(s) not supported or source(s) not found

下载文件: https://xyztecvideos.b-cdn.net/SMD%20shear%20test.mp4?_=1

Sigma ideal for SMD shear

Xyztec have a range of tests that can determine the effect on solder joint integrity resulting from reduced scale. The Sigma’s Revolving Measurement Unit (RMU) enables up to 6 different sensors or tools to be easily and quickly selected to suite a wide range of component and test requirements. Our pull, shear and tweezer sensors can include rotation, enabling the tool to be aligned to and then test components in any orientation.

Standards

- AEC-Q200-006

Test features

- Rotating shear tools to test components at any orientation

- Deep Access SMD test

- Fully automated testing

- Temperature-induced stress test with heater work holder

- Sensor accuracy ±0.075%

- Round test tool recommended