Scratch/coating

Maintaining high-quality coatings, paint and films is an important requirement within the semiconductor industry. The xyztec “Scratch Test” (PDF) provides a new means of measuring the quality of the adhesive bond of single or multiple coatings to the substrate and/or each other.

As shown in the video a special shear tool is used to land on to a coating or multiple coatings and then scratch along the surface. Another excellent solution is to use a diamond Nano Indenter tip.

What is the quality of your coatings?

Media error: Format(s) not supported or source(s) not found

下载文件: https://xyztecvideos.b-cdn.net/Scratch-Coating%20test.mp4?_=1

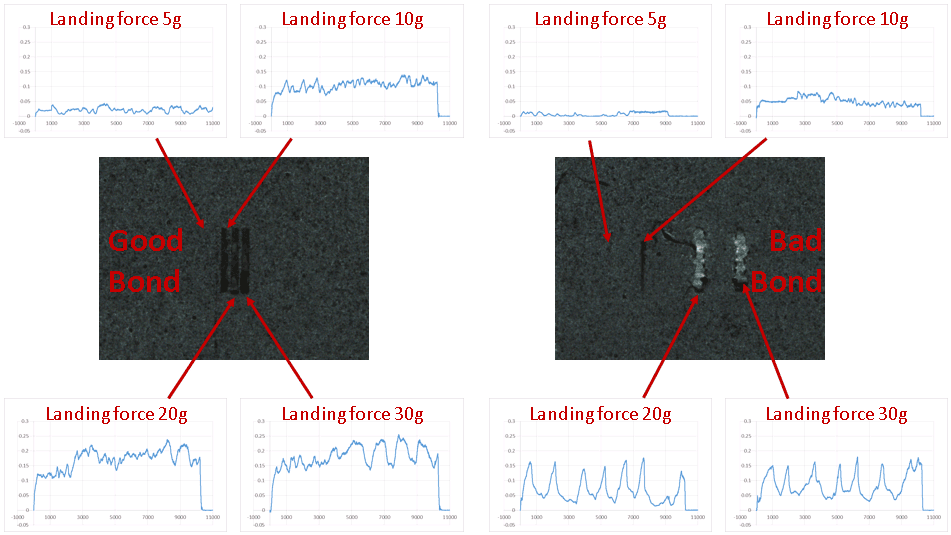

The depth of the cut and layer being tested can be controlled by a programmable landing force and the ability to drive down into the coating or coatings to a programmable depth. Weak bonds can be seen in the failure mode of delamination and the force-displacement graph of the shear tool. In the example shown the difference between a good and bad bond can be clearly seen.

There are three standard procedures for scratch testing;

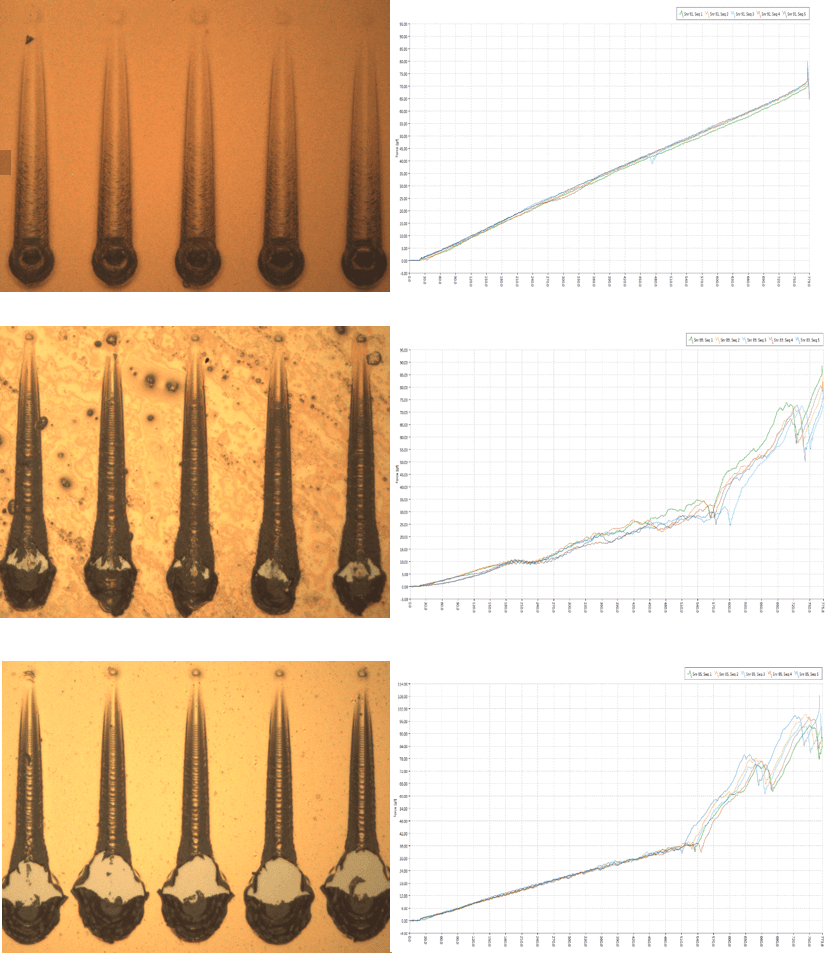

- Progressive Load Scratch Test (PLST)

- Constant Load Scratch Test (CLST)

- Multipass Scratch Test (MPST)

As with any scratch tester the quality of the bond between layers can be seen in the failure mode and force displacement graph. The examples in the picture below show the same PLST on multilayer films of different constructions.

Additional failure mode analysis such as EDX helps to show at what point layers fail. With this deeper understanding quality assurance may subsequently only require scratch testing.

The Sigma is a highly flexible micro materials tester specifically designed for the semiconductor and electronics industry. From its very beginning it was designed for easy and comfortable manual use, making it much faster than any dedicated scratch tester.

Its fully automatic mode delivers even more benefit. Samples are simply loaded and tested. The Sigma has fiducial mark pattern recognition to locate the samples position and then tests with precision with whatever combination of scratch tests you want. These can be different positions, procedures, directions and speeds. Being automatic, every sample is tested in exactly the same way.

In a recent application, a product that required 1 day to test takes a mere 2 minutes on the Sigma!