MIL-STD-883 method 2024.2 – Lid torque for glass-frit-sealed packages

Purpose

The purpose of this test is to determine the shear strength of the seal of glass-frit-sealed microelectronic packages. This is a destructive test.

Apparatus

The test equipment shall consist of suitable fixed or adjustable clamps and fixtures to secure devices while applying a torque to the seal area. The torque mechanism and holding fixtures should provide adequate support to the base and lid (especially for flat packs, chip carrier packages, or other thin profile packages) to assure that the torque is applied predominantly to the seal area without significant bending, warping or displacement of the package being tested. A torsion wrench or torque-applying mechanism capable of applying a torque of at least 12.8 newton meter (114 in-lbf) with a gauge capable of measuring the force with an accuracy and precision of ±5 percent of the reading or ±0.2 newton meter, whichever is greater, shall be used to apply torque to the lid. For smaller seal area packages a torsion wrench or torque-applying mechanism with sufficient capacity to separate the package and with an accuracy and precision of ±5 percent of the reading or ±0.2 newton meter whichever is greater, may be used to allow for a more accurate reading. The torque mechanism shall have a peak indicator for retaining the maximum stress applied or other equivalent stress recording system.

Procedure

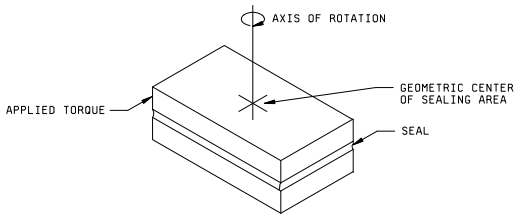

The device shall be held by the device body and torque applied to the lid of the device or vice versa. The lid torque fixtures shall be placed to assure that it only applies torque to the side area of the package lid, base, or spacer. Contact to the sealing glass should be avoided. The lid torque fixture may touch the package leads but not in such a way that significant torque is transferred directly through the leads. The torque shall be applied gradually and smoothly until package separation occurs, or the reaching of the 12.8 newton meter torque limit. The torque required for package separation or the reaching of the 12.8 newton meter torque limit shall be recorded. The torque shall be applied such that the axis of rotation is perpendicular to the sealing plane and the axis of rotation shall be located at the geometric center of the sealing area (see figure 2024-2).

Separate glass seals

For packages with more than one glass-frit-seal (e.g., separate glass-frit-seals for the lid and the lead frame), each seal shall be torqued and rated separately against the failure criteria. A failure of either seal shall constitute failure of the test. Alternatively, the two seals may be simultaneously stressed by holding only the lid and base and applying the torque specified for the larger seal area.

Failure criteria

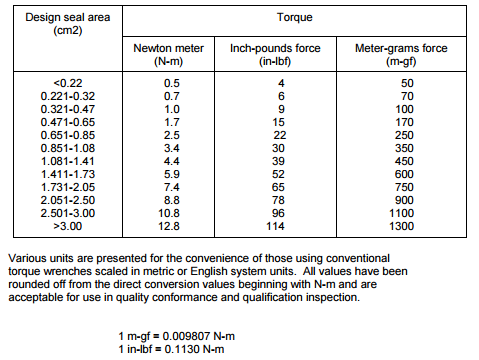

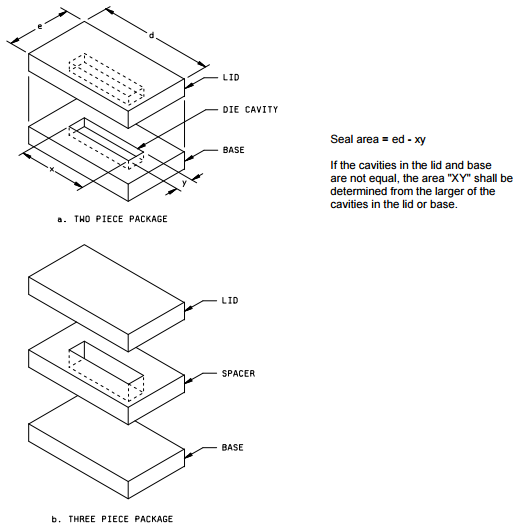

Failure criteria are based on not achieving the designated torque without breakage or lid separation. The designated torque is a function of the device seal area, as illustrated in Figure 2024-1. A device where package separation or breakage occurs at a torque value less than specified in table I shall constitute a failure. If the entire package (lid, seal, and base) breaks in a direction normal to the plane of the applied torque (i.e., showing evidence of improperly applied torque) with parts of lid and base still fused together, the package may be discarded without counting as a failure and a replacement sample substituted to complete the required testing.

Summary

The following details shall be specified in the applicable acquisition document:

-

- The minimum torque if other than the value specified in table I.

- Number of devices to be tested.

- Requirement for data recording where applicable.

End of 2024.2

Learn more about lid torque for glass-frit-sealed packages and see a video of a real test.