At Xyztec, we take pride in pushing the boundaries of bond testing technology and delivering tailored solutions to meet your unique testing needs. Our dedication to customization is unmatched. A remarkable 75% of our clients seek custom bond testing solutions.

As a technology leader, we rise to the challenge, providing market-leading bond testing systems and crafting custom software solutions, work holders, and systems to address your requirements.

Let us showcase our expertise in customization with 3 recent projects:

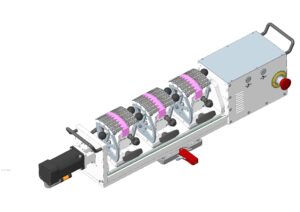

Rotating indexable work holder for circular parts

For many samples, straight and flat is the norm, but sometimes, our customers present us with unique challenges. When faced with a half-round sample, we introduced the Trunnion Style Stage (XWM690011). This motor-driven marvel precisely rotates the sample, allowing for testing all bonds on the product’s perimeter. 3 user-friendly Folding Clamping Carriers (XWC690593) ensure quick and secure sample handling. This design’s elegance lies in its seamless electronics integration, allowing you to switch work holders in seconds, making calibration and testing more efficient.

Key to this design is the seamless integration of electronics on the Trunnion Style Stage, requiring only 3 cable connections. This feature ensures swift work holder changes for calibration or testing other samples using standard work holders. To improve efficiency, the Folding Clamping Carriers provide seamless operation by employing pivoting clamp fingers and ergonomic handles, guaranteeing error-free sample loading.

Safety first with Sigma Safety Cover

To enhance operational safety, let us introduce the Sigma Safety Cover for our standard Sigma bond testers. This protective cabinet grants operators complete access to the machine without risking interference with moving parts. The cabinet features ESD-safe transparent plastic, ensuring visibility while also providing protection. With auto-locking doors and external control buttons, it’s ideal for automation in production environments and can also be modified for Sigma W12, ensuring safety across various models.

Indexing lead frame solutions

Automation is the future, and we’re at the forefront of innovation. Our indexing work holders are designed to accommodate various lead frame sizes, offering flexibility and efficiency. Instead of creating a work holder for each sample, we provide indexing work holders that can adapt to different lead frame sizes. Our advanced solutions include an automatically adjustable track for precise width matching, allowing step-by-step testing of multiple columns. Custom masks and inlays for each product group ensure accurate testing.

Our Sigma MAG systems take automation to the next level with a magazine handler, streamlining the testing of multiple lead frames. To fully embrace Industry 4.0, our Sigma MAG systems can be managed using GEM300 and automated with OHT or AGV robots. Powerful software tools automate grading and reduce the need for operator input.

These innovations and powerful software tools streamline testing and reduce reliance on manual input. Even if full automation is not your current need, our indexing work holders can greatly reduce setup time, allowing your operators to focus on actual testing.

Feel free to contact us to discuss your challenging samples and explore how our customization and innovation can help you meet your testing goals. Xyztec is here to provide tailored solutions for your unique needs.

Get your free Productronica ticket!

Xyztec is exhibiting at the Productronica 2023 in Munich (Germany) from 14-17th November. Get your free Productronica ticket by emailing your full name, telephone number, and company name. You will receive the corresponding code from us to register for Productronica 2023. Hope to see you at our booth in Hall 2A – Booth 316.