We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

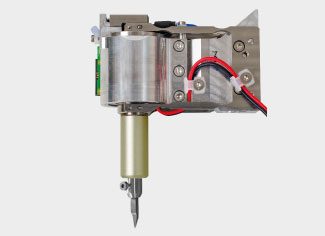

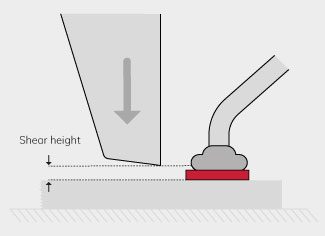

在推拉力测试机中,推力高度是最具挑战性的对位项目之一。测试之间的差异可能会影响测量结果,并使测试结果不太可靠。具有革命性的纳米控制剪切力传感器通过在剪切力传感器体内集成独特的驱动器和闭合控制回路来解决所有这些问题。

传感器在测试期间补偿了推力高度的任何变化,并使键合测试期间的推力高度完全可追溯。它是测试精度要求高的应用(如晶片级、涂料和引线框架)的绝佳解决方案。

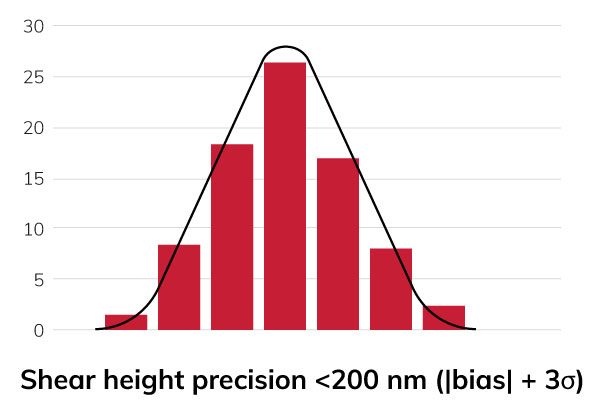

专利的纳米控制剪切力传感器在编程推力高度的200纳米范围内始终保持一致,并在测试期间保持此对位。传感器通过使用内部驱动器和闭合控制回路在测试期间补偿了剪切高度的任何变化。与利用夹紧和其他步骤的传统方法相比,到达推力高度的移动速度更快,从而提高了Sigma键合测试器每小时的测试数量。

剪切高度控制中另一个难以控制的方面是landing force与待测物接触力。所有Sigma剪切力传感器都包括一个垂直力传感器,为其提供独特的可编程landing force功能。没有其他推拉力测试机可以实现下至5 gf的landing force。

通过革命性的纳米控制剪切力传感器最大化每小时测试次数。该剪切传感器到达推力高度的速度比传统剪切力传感器更快。

Sigma已经是市场上最快的推拉力测试机。通过经验丰富的用户证明,与大多数竞争系统相比,Sigma的UPH最高可快39%。纳米控制剪切力传感器显着地最大化了每小时测试数量(UPH)。

下面的测量报告显示,重复性远低于规格的200纳米。为了调查,推掉20个垫(bump),编程推力高度为2.3微米。 Bruker白光干涉仪测量了所有被推完bump剩余的实际高度。推力高度的标准偏差仅为35纳米。纳米控制剪切力传感器的稳定性在行业中设定了一个新的革命性标准。

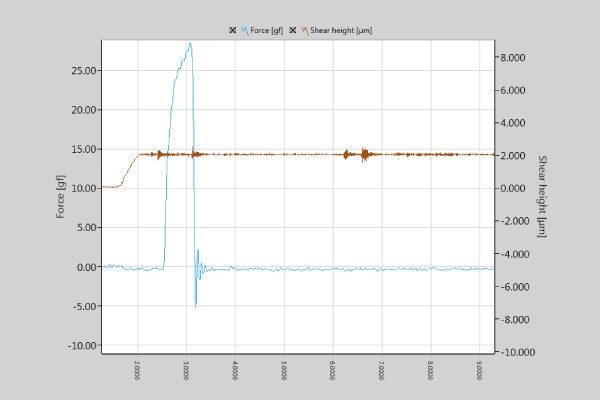

除了在推力高度方面实现和保持前所未有的精度外,Sigma推拉力测试机还会在测试期间记录剪切高度。测量的剪切高度可以在力图上的二次垂直轴上显示,因此首次可以追溯。

纳米控制剪切力传感器与Sigma推拉力测试机和灵活的工作台结合使用,使以前被认为是不可能进行的键合推力测试成为可能,并极大地增强了其他现有测试的意义。这对于大多数晶片级测试、涂料测试和引线框架应用的测试尤其如此。

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

开发世界一流的结合力测试技术,并与全球合作伙伴一起在全世界提供当地服务支持。

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands