We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

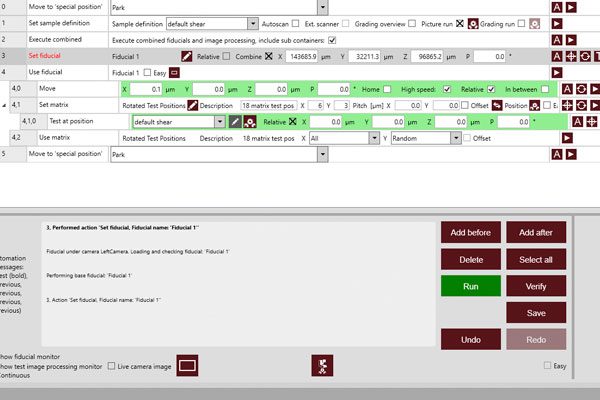

Our software comes with 2 levels of programming to make it approachable for operators and engineers to customize the widest range of manual and automated test sequences.

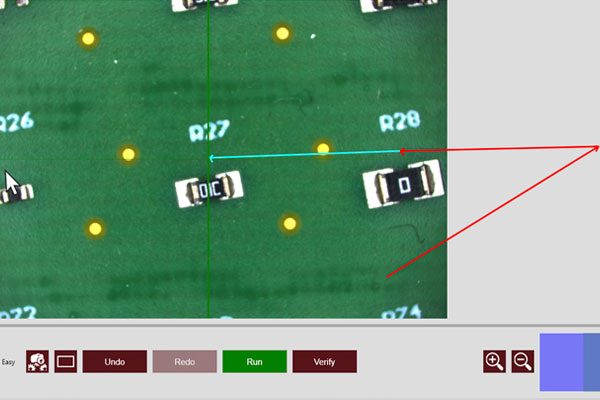

Everyone can easily create automations for less complex applications. Onboard graphics and intelligent wizards allow easy programming with limited automation commands for one default test method. The software ensures complete documentation of the test protocol, provides preset configurations, and intuitive operator screens. Operators can start automations, created and maintained on engineering level, with a single click. (This level of programming is ideal for production environments).

The completely open editor allows engineers to customize test sequences and write scriptable test methods for any application. Experts are given the flexibility to combine multiple test types and/or methods in one automation. The software comes with numerous features for optimal customization to fully suit your requirements. This suite of advanced, flexible programming options can be hidden from operator levels or during day-to-day use.

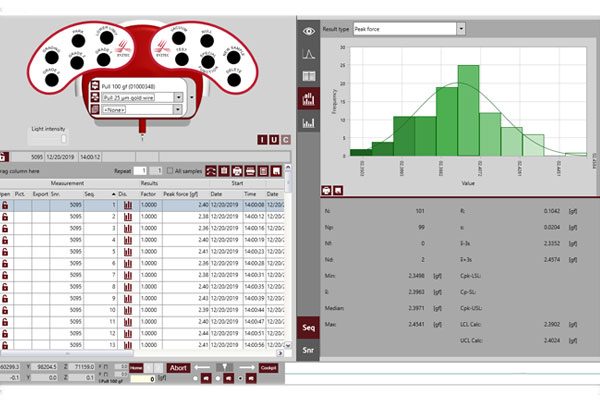

Statistical Process Control (SPC) offers comprehensive statistical information to analyze your production process. This includes different types of graphs to view on screen or to print as reports.

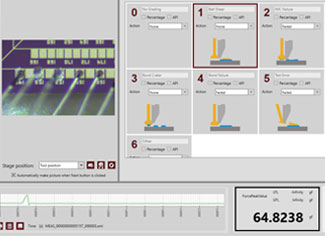

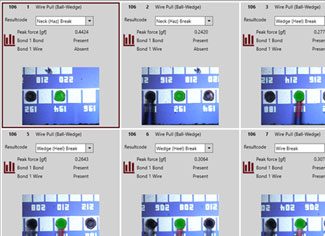

Performing a grading run allows you to sequentially evaluate the measurement results using the microscope or an offset camera and evaluate them with the correct grading.

Accelerate the grading process with a grading overview. After multiple tests, an overview presents all measurements to evaluate the abnormalities and determine the correct grading of the failure modes.

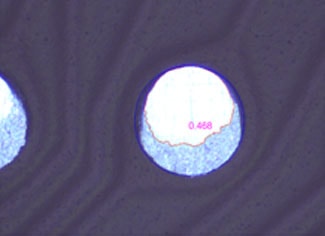

Automated Optical Inspection (AOI) grades the area of bulk material remaining as a percentage of the whole. This generates more reliable measurement results by designing out operator influences.

A “test format” function previews the output of the configuration using demonstration data. You can setup various fields of the test data:

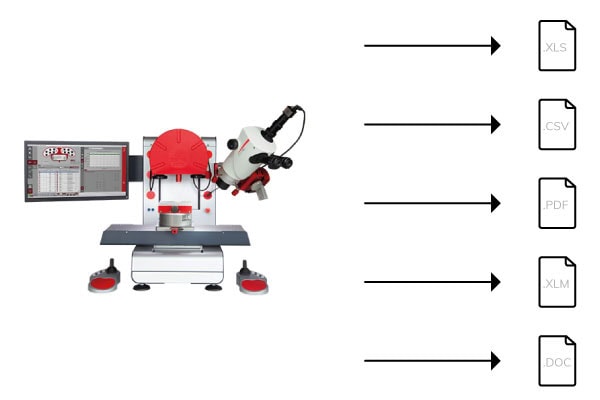

The built-in data export editor allows you to configure your reports in almost any format (PDF, XML, XLS, DOC, and more.) to be saved to a file or clipboard.

Automatically store the reports after several measurements. The editor supports export to file, serial port, clipboard, and other protocols.

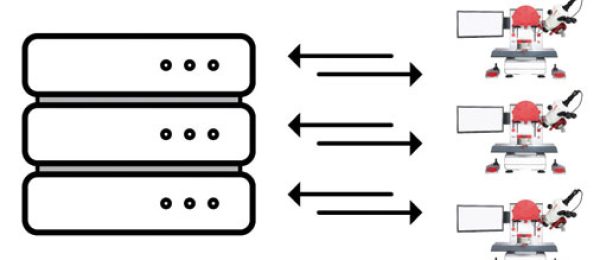

If you own multiple bond testers a centralized database greatly enhances SPC. Easily harmonize test method settings and data between several machines and a central database to improve measurement traceability.

Advantages of a centralized database:

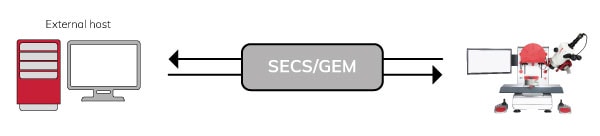

The software supports SECS/GEM and SMIMA protocols.

SECS/GEM is an equipment interface protocol for equipment-to-host data communications in the semiconductor industry. Test results, images, and data can be exported and stored. We offer SECS/GEM communication directly in the Sigma software or via an EFEM.

As market leader around the world, our support is international. We offer remote access support and video software training.

Our skilled engineers, based all around the world, work together with global partners to provide local support worldwide.

Software updates come with the matched fully tested firmware embedded. This ensures that whatever software version you use, the hardware will use exactly matched and fully tested firmware revisions and allows you to easily up and/or downgrade at any time.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands