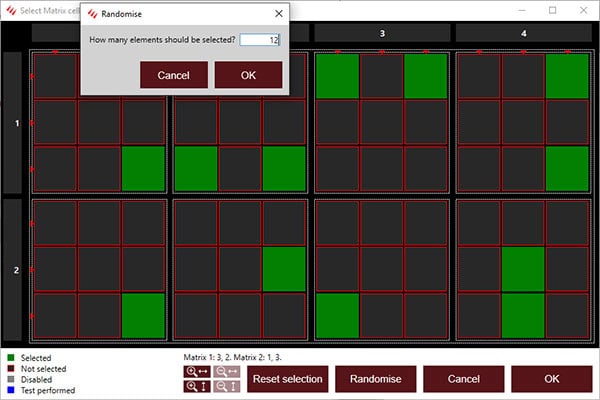

Matrix programming allows you to test a variety of position types, including repeating positions, like:

Quickly test whole waffle trays of samples without operator intervention. You can program a waffle tray loader on your Sigma MAG to pick the sample from the waffle tray and place the sample into the clamper and vice versa.

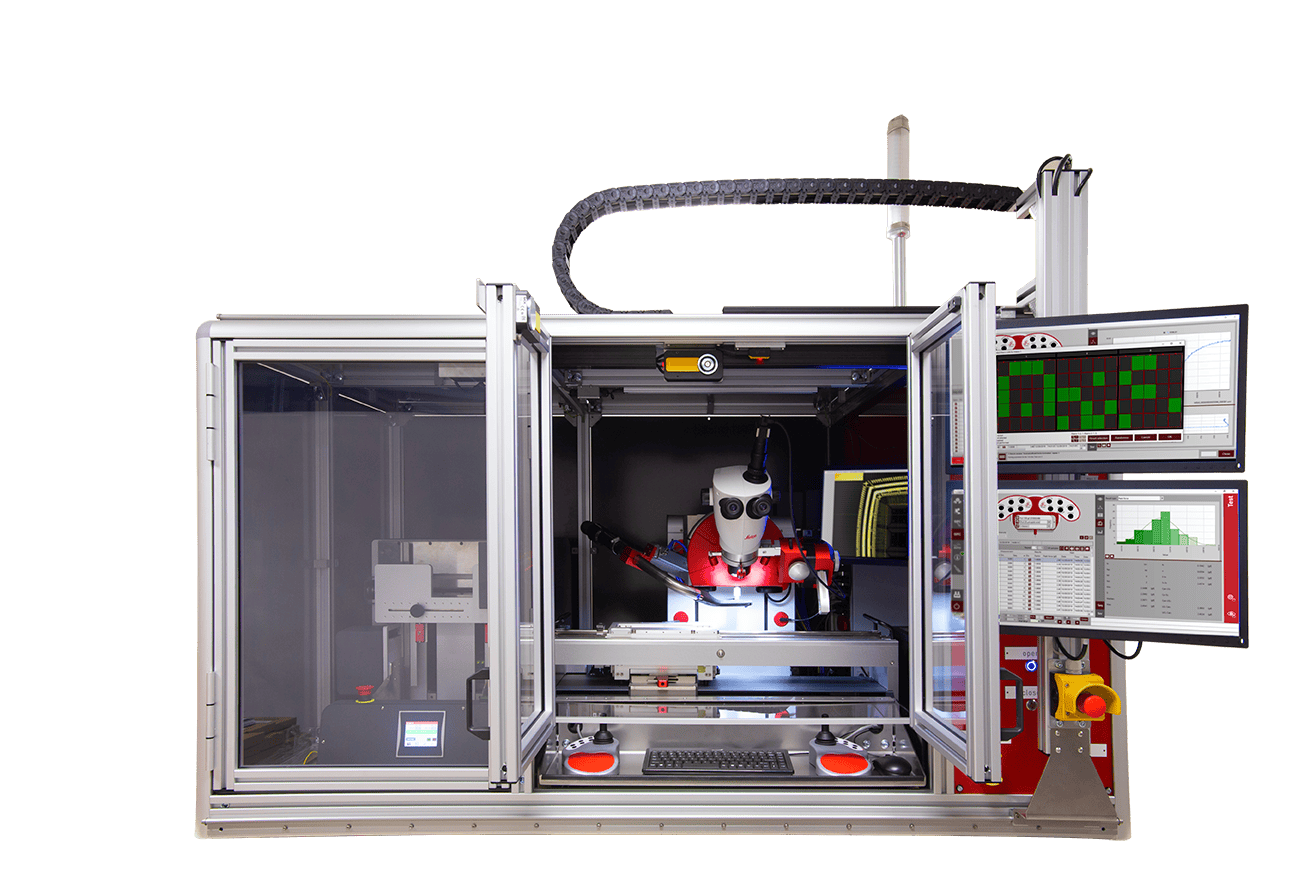

This option guarantees extra safety during automatic bond testing and protects the operator from moving parts. The cabinet fulfills the standards for safety and ergonomics, and it keeps the test debris away to ensure a clean working environment.

The Loadport is an extension to the Sigma MAG for automatic (un)loading of magazines up to 100×240 mm without operator intervention. It communicates through SEMI E84 and allows top- and frontloading by:

Magazine buffering makes lead frame testing even more efficient. It is possible to load multiple magazines to keep the system running and ensure no down-time on the bondtester.

Like the Sigma MAG, the Loadport comes with a safety enclosure and is compliant to SEMI S2/S8. The frontside of the Loadport is open but has safety light curtains. When the operator reaches through the light curtains, the system shuts down immediately to guarantee optimal safety protection.

Eliminate human error and save production costs.

Robotic handlers

Robotic handlers

Easy programming

Easy programming

Smart vision cameras

Smart vision cameras

Tool alignment

Tool alignment

Fiducial recognition

Fiducial recognition

Wire detection

Wire detection

Grading run

Grading run

Auto grading

Auto grading

Image measurement (AOI)

Image measurement (AOI)

Data communication

Data communication

Robotic handling ensures safe load and unload of applications and avoids handling error and damage. We offer handlers for:

The open Sigma software enables easy programming of total automation steps, positions, and commands. The automation editor employs camera visualization and intelligent wizards.

See the unseen with up to 3 live camera options. Bring out the features of interest with images or videos using high-resolution cameras, flexible LED illumination, and fantastic image processing options.

Recognition of components and fine pitch wires that are swept out of position due to process tolerances or part handling.

A Sigma offers 2 alternatives to make grading more efficient and consistent:

Improve data processing using automatic export and SECS/GEM for tracking and control.

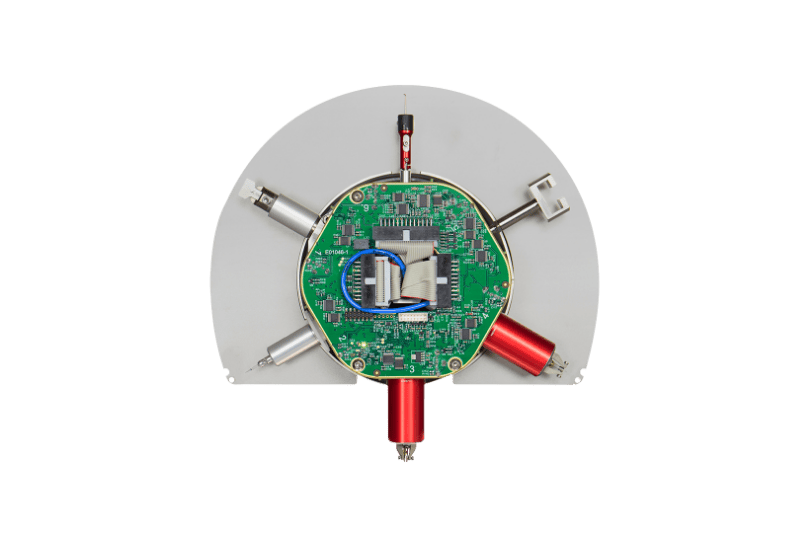

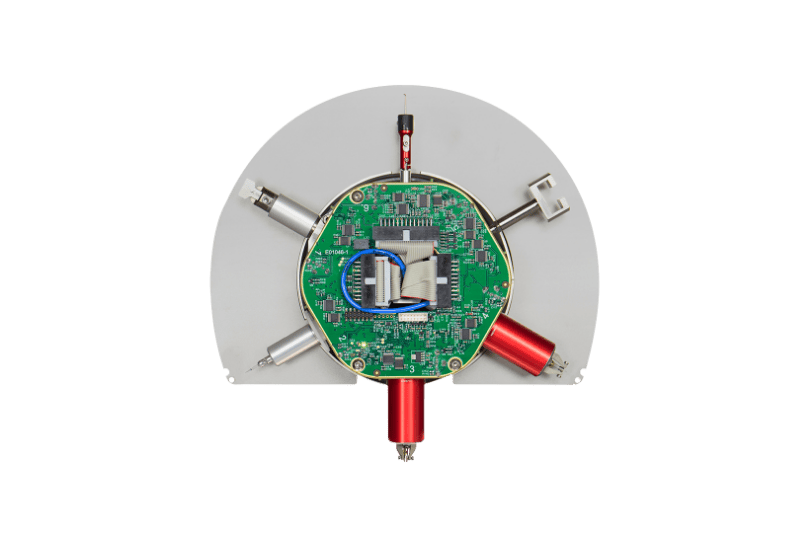

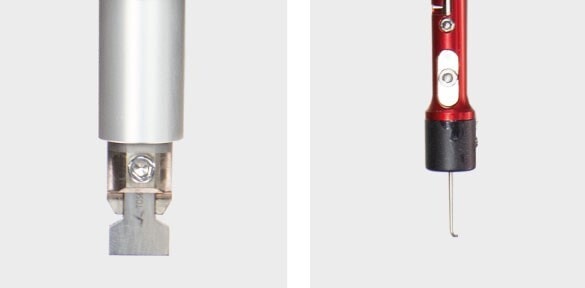

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

The nano control shear sensor has a unique drive with a closed control loop within the shear sensor body. It improves the accuracy and stability of the shear height with a precision of 200 nm when testing critical applications such as wafer-level, coating, and lead frames.

| STAGES | SIGMA MAG |

|---|---|

| X-stage (mm) | 600 |

| Y-stage (mm) | 168 |

| Z-stage (mm) | 168 |

| Axis speed (mm/s) | 50 |

| Resolution linear encoders (backlash free drives) (nm) | 30 |

| Digital temperature correction | |

| ACCURACY | |

| Accuracy (%) | 0.075 |

| ADC resolution (bit) | 24 |

| Sampling frequency (kHz) | 10 |

| Shear height (step back) accuracy ±1 μm | |

| Programmable landing force down to 5 gf | |

| MECHANICAL | |

| Footprint X (mm) | 1800 |

| Footprint Y (mm) | 900 |

| Height (mm) | 1100 |

| Weight (± kg) | 160 |

Please contact us for more information and options for your factory. Specifications are subject to change without prior notice.

![]() Standard

Standard![]() Optional

Optional![]() Not available

Not available

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Dirk Schade