Sigma bond testers are modular by design and come with game-changing automation capabilities for automatic loading, testing and analyzing. The Revolving Measurement Unit (RMU) houses up to 6 sensors that enable continuous testing. The software includes vision and deep learning technology to eliminate human errors.

Integrate the Sigma W8 with an independent wafer (un)loader for hands-free bond testing. The wafer handler automatically loads, aligns and transfers the wafers from the cassette onto the bond tester. The cassette mapper detects empty slots and ensures safe wafer handling.

The system gently secures flat and warped wafers with the soft, flexible tips on the PID controlled wafer lift pins.

The Sigma W8 is upgradeable to the market-leading Sigma W12 bond tester, which can test wafers up to 12 inches (300 mm) fully automatically. The Sigma W12 comes with a 600 mm X stage to test bumps down to 20 µm. The upgrade possibility makes the Sigma W8 a future-proof investment.

Eliminate human error and save production costs.

Robotic handlers

Robotic handlers

Easy programming

Easy programming

Smart vision cameras

Smart vision cameras

Tool alignment

Tool alignment

Fiducial recognition

Fiducial recognition

Wire detection

Wire detection

Grading run

Grading run

Auto grading

Auto grading

Image measurement (AOI)

Image measurement (AOI)

Data communication

Data communication

Robotic handling ensures safe load and unload of applications and avoids handling error and damage. We offer handlers for:

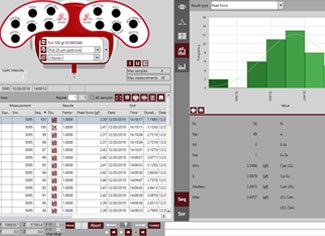

The open Sigma software enables easy programming of total automation steps, positions, and commands. The automation editor employs camera visualization and intelligent wizards.

See the unseen with up to 3 live camera options. Bring out the features of interest with images or videos using high-resolution cameras, flexible LED illumination, and fantastic image processing options.

Recognition of components and fine pitch wires that are swept out of position due to process tolerances or part handling.

A Sigma offers 2 alternatives to make grading more efficient and consistent:

Improve data processing using automatic export and SECS/GEM for tracking and control.

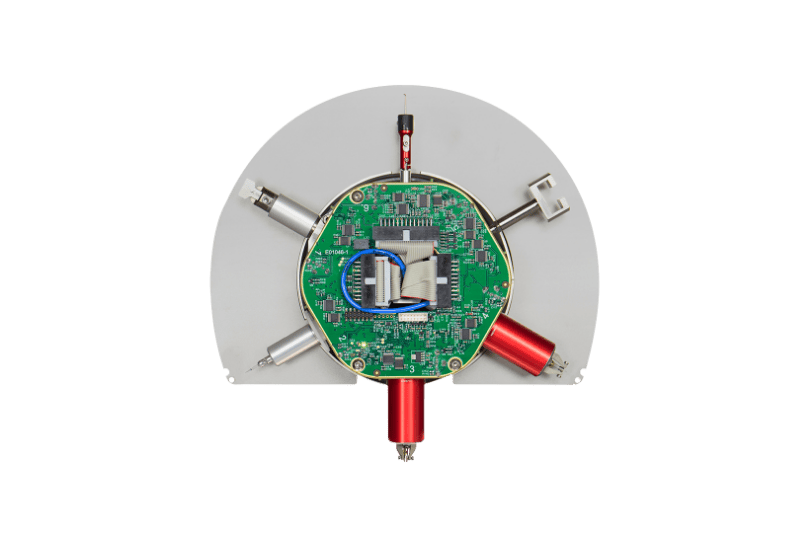

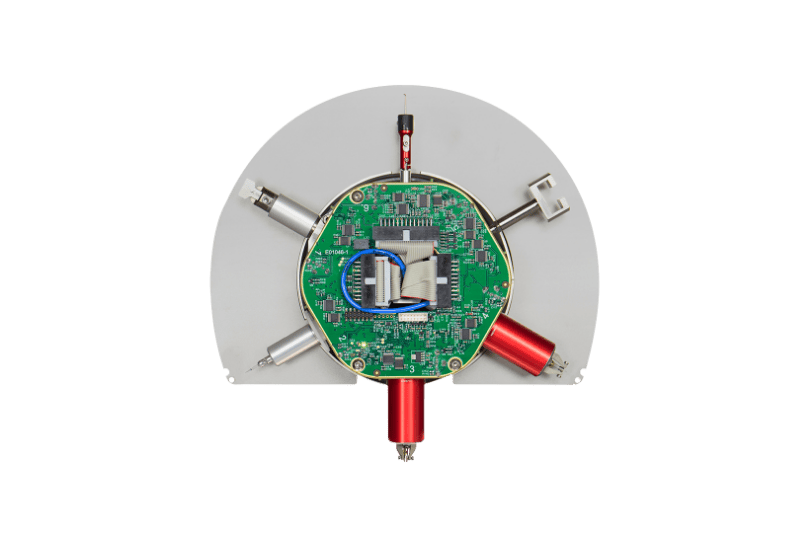

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

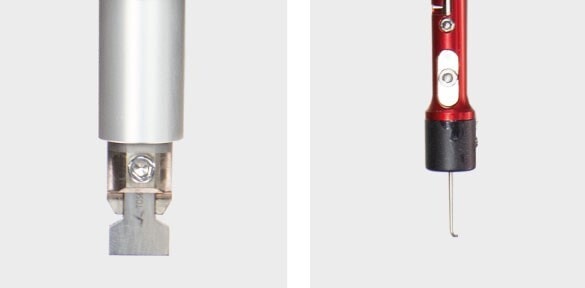

The nano control shear sensor has a unique drive with a closed control loop within the shear sensor body. It improves the accuracy and stability of the shear height with a precision of 200 nm when testing critical applications such as wafer-level, coating, and lead frames.

| STAGES | SIGMA W8 |

|---|---|

| X-stage (mm) | 370 |

| Y-stage (mm) | 370 |

| Z-stage (mm) | 168 |

| Axis speed (mm/s) | 50 |

| Resolution linear encoders (backlash free drives) (nm) | 30 |

| Digital temperature correction | |

| ACCURACY | |

| Accuracy (%) | 0.075 |

| ADC resolution (bit) | 24 |

| Sampling frequency (kHz) | 10 |

| Shear height (step back) accuracy ±1 μm | |

| Programmable landing force down to 5 gf | |

| MECHANICAL | |

| Footprint X (mm) | 620 |

| Footprint Y (mm) | 935 |

| Height (mm) | 608 |

| Weight (± kg) | 100 |

Please contact us for more information and options for your factory. Specifications are subject to change without prior notice.

Standard

Optional

Not available

Dirk Schade