We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

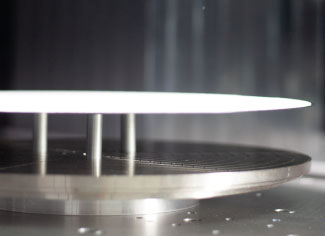

Gently secure flat and warped wafers because of the soft, flexible tips on the PID controlled wafer lift pins. Vacuum sensing and switching are intelligently timed with the lift pin position throughout the load, clamp, and unload cycle.

In cases of extreme warpage, an optional wafer pusher ensures precise clamping. The high airflow of vacuum chucks pulls down wafers.

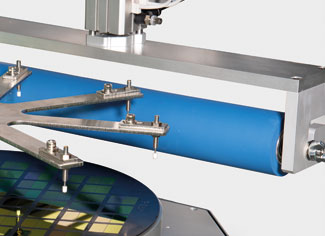

Keep test debris away from the wafer or the wafer chuck with a blower and vacuum cleaner or a roller with sticky foil, for pre- and post-cleaning.

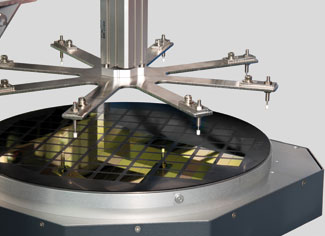

Integration transforms the bond tester into a fully automated system. We offer various types of wafer handlers (Equipment Front End Module), for operator-free bond testing.

Vacuum work holder for panels or wafers up to 300 mm. Easily reach 100% of a 300 mm panel without repositioning your sample on the chuck. The wafer chuck work holder comes with safety interlocks and 360° rotation.

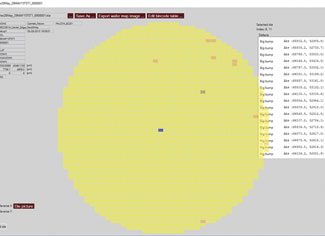

Easily import and export multiple file formats for wafer maps such as KLARF, (S)INF, G85, and others for full traceability. Defects or test positions are shown in an overview and are directly accessible for testing or analysis.

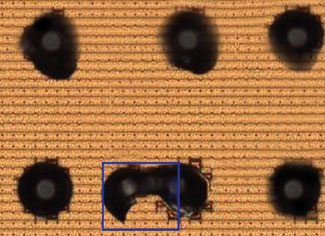

Automatically shear the big bumps and clean the debris to prepare for wafer probing. Fully programmable vision algorithms can check if the removal of big bumps was successful.

The solder that builds up in the cavity of the Cold Bump Pull (CBP) jaw reduces the gripping efficiency. This contactless cavity cleaner melts the solder with a high temperature and high-pressure air jet and then blows it into a fine matrix where it is absorbed.

Eliminate human error and save production costs.

Robotic handling ensures safe load and unload of applications and avoids handling error and damage. We offer handlers for:

The open Sigma software enables easy programming of total automation steps, positions, and commands. The automation editor employs camera visualization and intelligent wizards.

See the unseen with up to 3 live camera options. Bring out the features of interest with images or videos using high-resolution cameras, flexible LED illumination, and fantastic image processing options.

Recognition of components and fine pitch wires that are swept out of position due to process tolerances or part handling.

A Sigma offers 2 alternatives to make grading more efficient and consistent:

Improve data processing using automatic export and SECS/GEM for tracking and control.

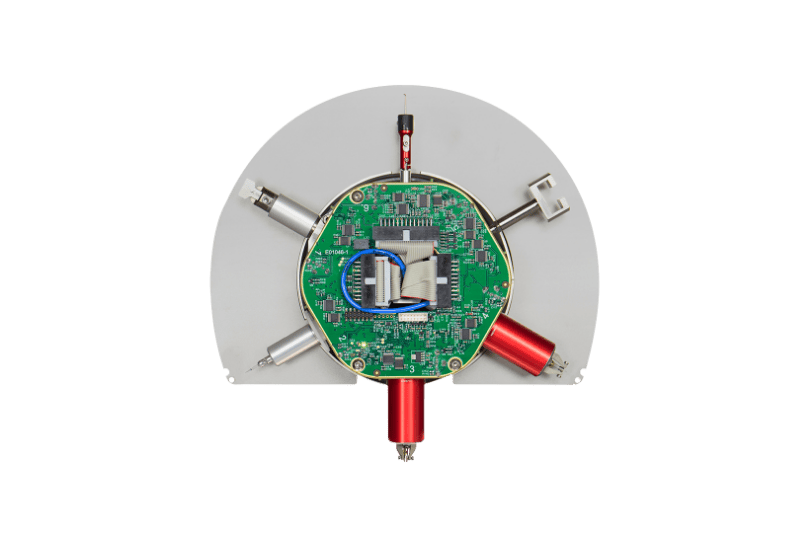

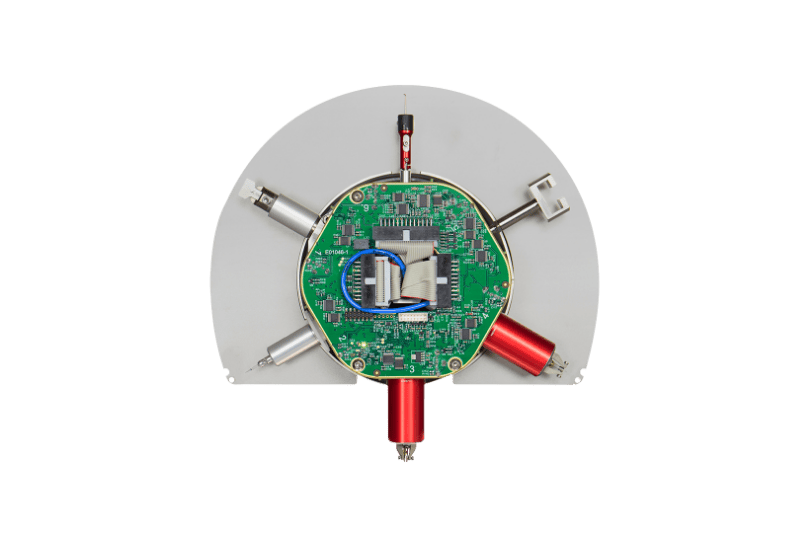

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

The Revolving Measurement Unit (RMU) houses up to 6 flexible sensors that are configurable with various pull, peel, push, or shear tools. This enables continuous testing up to 200 kgf.

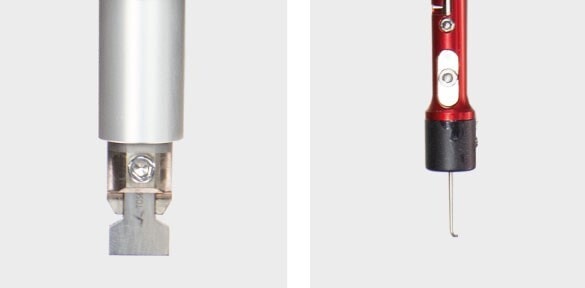

The nano control shear sensor has a unique drive with a closed control loop within the shear sensor body. It improves the accuracy and stability of the shear height with a precision of 200 nm when testing critical applications such as wafer-level, coating, and lead frames.

| STAGES | SIGMA W12 |

|---|---|

| X-stage (mm) | 500 |

| Y-stage (mm) | 370 |

| Z-stage (mm) | 90 |

| Axis speed (mm/s) | 50 |

| Resolution linear encoders (backlash free drives) (nm) | 30 |

| Digital temperature correction | |

| ACCURACY | |

| Accuracy (%) | 0.075 |

| ADC resolution (bit) | 24 |

| Sampling frequency (kHz) | 10 |

| Shear height (step back) accuracy ±1 μm | |

| Programmable landing force down to 5 gf | |

| MECHANICAL | |

| Footprint X (mm) | 1300 |

| Footprint Y (mm) | 935 |

| Height (mm) | 608 |

| Weight (± kg) | 100 |

Please contact us for more information and options for your factory. Specifications are subject to change without prior notice.

![]() Standard

Standard ![]() Optional

Optional![]() Not available

Not available

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands