Wedge shear

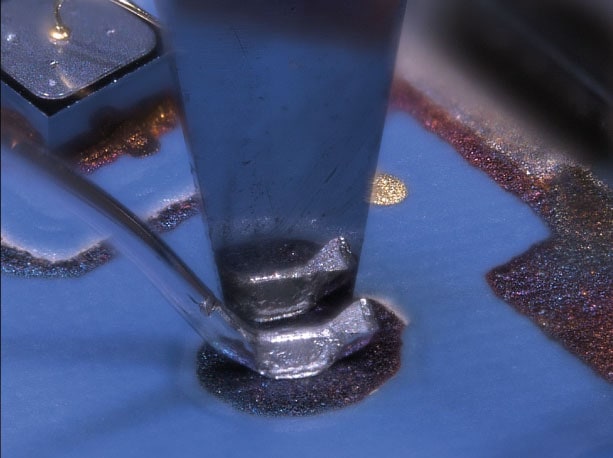

Wedge shear test and wire pull tests are used to assess the quality of bonded aluminum or copper wire and ribbons. The wedge shear test is comparable to other shear tests. After an automatic touchdown, the Z-stage will move up with the predefined shear height. This touchdown and the shear height must be very accurate to make sure that the measurement results are correct and the IMC is not damaged or smeared.

Equally important is the shear tool. Due to the high forces that can occur during this test, the tool must be adapted to the wedge. Xyztec can offer standard tools and customized deep access tools. This test is used by companies that produce microwaves, high frequency, power, automotive, hybrid and solar devices.

How to: Wedge shear

Test features

- Shear test from a few grams up to 1000 kgf

- Sensor accuracy ±0.075%

- Shear height accuracy ±1µm

- Complies with industry standards

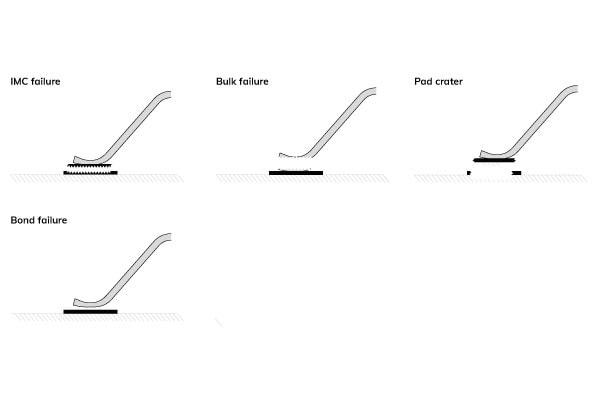

Failure modes

Failure in IMC

- Bond strength known

- Acceptability depends on the strength

Failure in bulk material

- Bond strength not known

- Bond strength good or bond test bad

Pad crater

- Pad strength known

- Acceptability depends on the strength

- Possibly bonder process problem

Bond failure

- Bond strength known

- Acceptability depends on the strength

- Probably very weak bond