We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

70-75% of our customers are looking for custom items. As the technology leader, we take on the latest challenges in bond testing and anticipate future market demands. Besides a wide range of standard tools and work holders, we design custom bond testing solutions to fulfill all test requirements.

Whether you require custom tools or more complex solutions like work holders or complete bond testing systems, at xyztec, our team has the experience and expertise to create the unique solution you need:

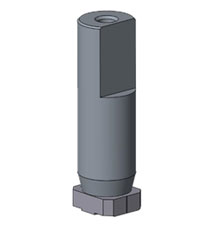

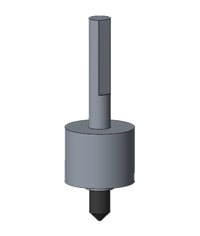

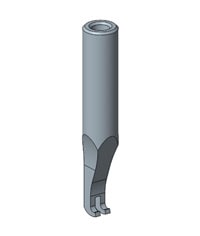

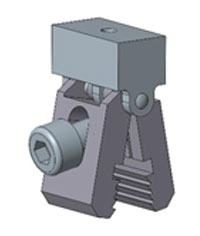

Shear tool

Shear tool (back relief)

Deep access tool (extra long)

Self alignment shear tool

Scratch tool (diamond tip)

Cavity shear tool

Push tool

Pull tool

Ribbon pull tool

Push tool

Cut tool (exchangeable knife)

Pull tool

Wedge pick up tool (tweezer tip)

Heavy load tool

Toothed tweezer tips

Wide toothed tweezer tips

Stud pull tweezer tips (glass stud)

Stud tool

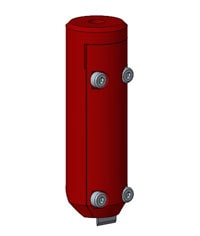

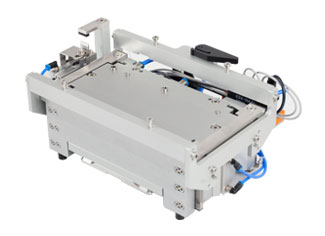

Test entire battery modules without the need to manually rotate the module mid-testing. For this custom solution, we use a Sigma W12 bondtester for 300 mm wafers as a baseline and add a custom sliding work holder that allows fully automatic testing across the entire battery module.

The custom pneumatic stage extension increases the testable reach in X beyond the standard 600 mm to a maximum of 900 mm. By extending the machine body and mounting the RMU farther from the rest of the system, the Y-axis is now 370 mm, a 120% increase relative to a standard Sigma.

This work holder solution is just one example of our ability to generate custom solutions to meet unique customer requirements. We offer bond test systems for all battery pack sizes, including bench-top and floor model solutions to test heavy applications or battery packs.

Warm up your samples to high temperatures to test epoxide or soldered interconnections. Especially useful for shear testing on large rectangular glass carriers.

The (hot) panels are easy to handle by using the sample carrier and cooling down rack. Triple heat shielding around the test head makes sure that the prolonged high temperatures do not affect the inner working of the Sigma bond tester.

An extremely flat aluminum table delivers a perfect vacuum. With 27 heater elements in 7 different control groups, the Sigma quickly warms up its table and the sample with high accuracy and consistency.

With a Sigma combined with micro dispenser and tweezer you can perform a very reproducible destructive stud pull test on 3D MID (Molded Interconnect Device) such as (glass) surface coatings.

The micro dispenser drops small amounts of glue (microliter amounts) very accurately. It makes an adhesive connection with the carrier (or test object) by using a stronger glue than the bond. A special UV light on the machine cures the glue within seconds.

Tweezers automatically take glass studs from a magazine using exclusive tipsand place them with a predefined pressure on the surface with the glue. The push force is just sufficient to get a strong connection, without forming any menisci.

The tweezer holds the stud during the test. Automation ensures that the tweezer applies no unwanted load to the stud or influences the measurement.

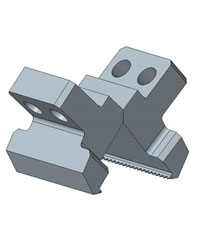

Work holder XWV690068

Work holder XWC690428

Work holder XWU690079

Work holder XWC690432

Work holder XWC690431-battery

Work holder for lead frames

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands