Xyztec has just introduced 2 new automated systems that may actually provide customers with a direct return on investment (ROI). The new Sigma platform has enabled huge leaps in capability.

Sigma bond tester

Bond testers are systems used to determine if a process meets a particular specification or a company’s internal bond strength requirements based on their experience. These systems have truly increased in sophistication over the past several years. Early testers were often put together by an engineer or a skilled technician… Historically bond testers were “must have tools”. They were a capital expense that customers needed to verify their processes.

Although bond testers have determined many process failures before they went to production, you could never claim that there was a return on your investment relative to reduced labor hours… there always had to be someone sitting in front of the machine!

Full automation: disruptive technology

Xyztec has changed that scenario. Using the software automation functionality built in to the latest Sigma models, an operator will now be free to perform some other assignments while the machine automatically tests the device. The built in cameras on the Sigma and W12 systems identify fiducial marks on the device under test (DUT) by using the pattern recognition software. Essentially, the operator teaches the system to recognize one or more fiducials. The operator then teaches the system moves based on the tests required for each device. Once established, all moves in the X, Y and Z axis are carried out per the saved automation routine. When changing from unit to unit, the alignment is now performed through the camera and software based on the established fiducial(s).

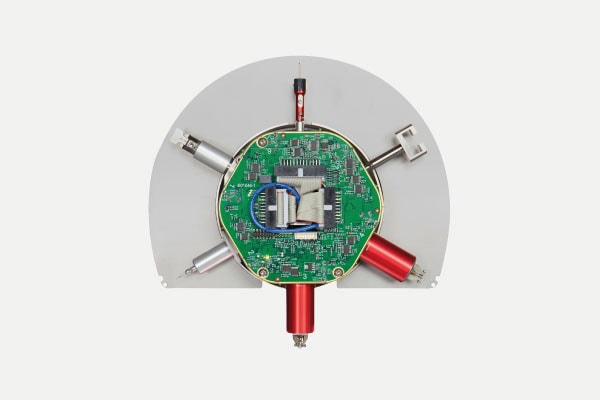

To further enhance this automation capability, it is possible to perform up to 6 different test types using the Rotating Measurement Unit (RMU). The device DUT remains in the same position regardless of test type. Within a few seconds, a new tool/sensor combination resumes the automation program. Customers have found this feature very helpful when trying to automate testing of devices that may incorporate multiple wire diameters, small and large chips, ball bonds, wedge bonds, etcetera. Again… there is no need for stopping the automation. During the test change, a tool automatically moves to a safe height, then a new tool/sensor combination is rotated in place and the automation resumes.