Die shear

Shear force can vary significantly depending on the type of bond (soldered, adhesive conductive, adhesive nonconductive) and the dimensions of the die. To cover this range, xyztec offers an extensive selection of tools and work holders. Additionally, customized tooling can be supplied.

How to: Die shear

Standards

Test features

- Die shear test from a few grams up to 1000kgf

- Eliminate die cracking with patented high force self aligning die shear tooling

- Automatic rotation alignment of tool to die

- Ultra thin die testing

- Soft shear option complies with industry standards

- Flip chip BGA testing

- Impact die shear test

- Sensor accuracy ±0.075%

- Shear and impact shear testing at up to 500°C

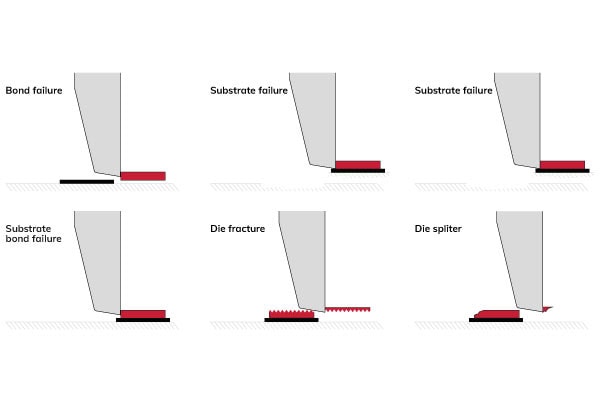

Failure modes

Die bond failure

- Bond strength known

- Acceptability depends on the strength

- Probably weak bond

Substrate failure

- Bond strength known

- Acceptability depends on the strength

Bond failure

- Bond strength known

- Acceptability depends on the strength

Substrate bond failure

- Bond strength known

- Acceptability depends on the strength

- Probably weak bond

Die fracture

- Bond strength not known

- Die strength known

- Acceptability depends on the strength

Die splinter

- Bond strength not known

- Acceptability depends on the strength

- Bad test or maximum test force possible

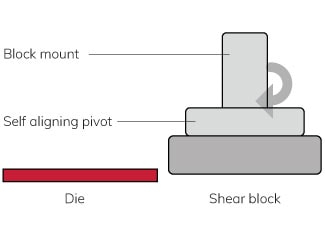

Self Aligning Shear test solution

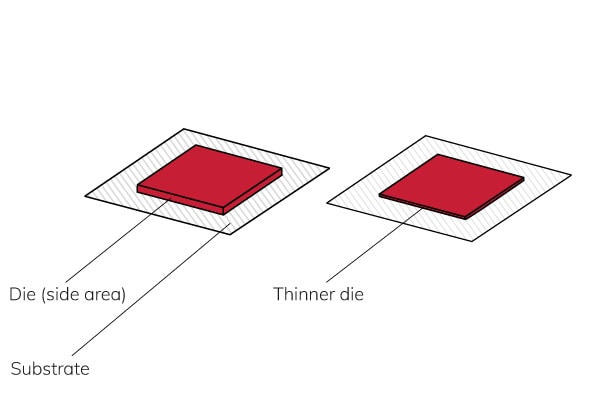

A fundamental problem exists when shear testing large die; the strength of the bond is in proportion to the area of the die but the area available to apply the shear load is much smaller being limited to that of one of its edges. As die become larger and thinner the relative sizes of these two areas can result in the stresses created by the shear tool being higher than the yield strength of the die causing it to splinter or shatter before the bond is tested.

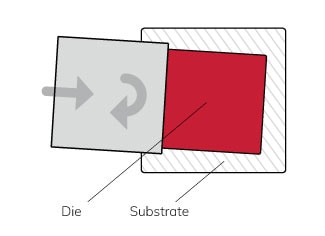

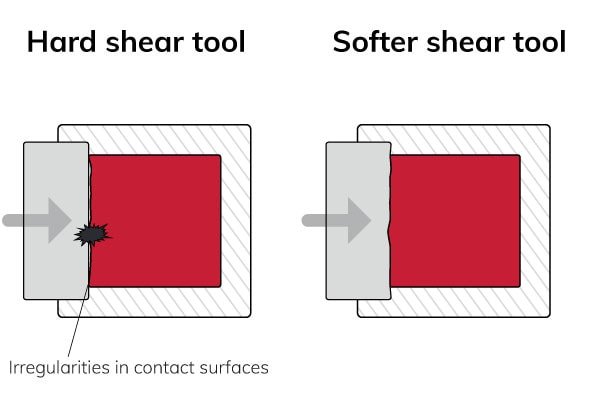

In many cases this undesirable effect can be eliminated with the use of XYZTEC’s latest shear tool development*. The part of the tool that contacts the die is a shear block. It should be a relatively soft material like aluminium or mild steel. Because it is softer than the die it deforms at the points of contact that inevitably result due to surface irregularities between the edge of the die and the tool tip. This deformation considerably reduces the high contact stresses that would otherwise cause the die to fail.

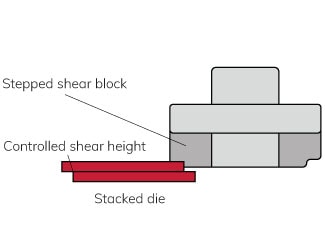

The shear block is held in place on a mount by vacuum. The block can rotate slightly (self alignement). Another feature is that its underside can include an undercut that ensures a precise shear height. Without this system deformations in the vertical axis caused by the very high shear forces can cause the shear tool either rise or fall relative to the substrate. If the tool lifts it increases the stress concentration on the edge of the die making die failure likely. This feature is ideally suited for testing stacked die which are very thin and require such precise control of shear height. xyztec offers a complete solution for die shear testing that consists of the self aligning tool and a special die shear work holder. This combinations supports high shear forces. The work holder also offers a protection cap for the safety of the operator and with specials masks it is possible to test dies on different angles and in different sizes.

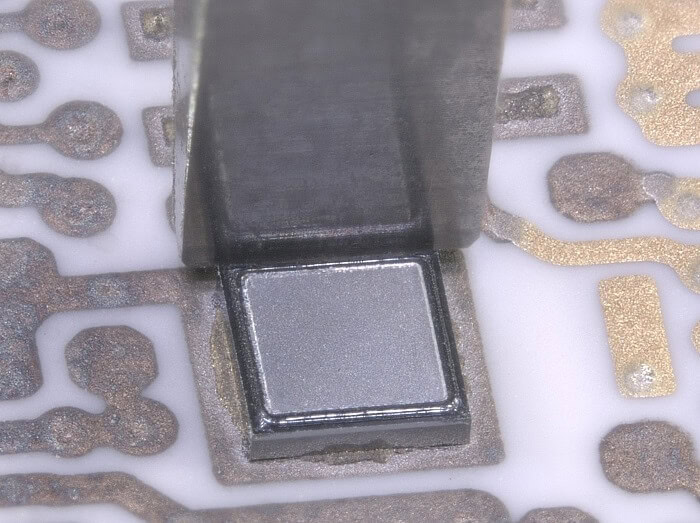

Cellphone display LCD driver IC testing

*Patent PCT/NL2010/050545, CN102770747, EP2473832, WO2011028107