Image capture

The xyztec Vision system is ideal for providing high-resolution images. These images can be used for customer presentations, operator training, or failure analysis reporting.

Software system

Our vision system is an integral part of the Sigma software. The standard image capture camera has an offset from the tool test point. If desired, the software can be set up to capture an image of a failed pull, shear or any other test just completed. With one click the system will instantly calculate the offset and move to the camera position to capture the image. Captured images are stored with the measurement data. The image can be recalled when necessary to enable further analysis.

Image options

xyztec offers three camera options as part of the image capture capability. In addition to the left side offset camera, we offer a right side offset camera that can be used in conjunction with a different objective for higher magnification or greater field of view. When two magnifications are required, two rigidly mounted cameras provide better inherent accuracy than one camera with a zoom.

We also offer a camera that can be mounted on a trinocular microscope or from the side. These cameras can provide live video capture. This is a great function for automation, teaching and data capture for customer presentations.

Built-in LED lighting

xyztec’s image capture system utilizes the latest LED technology. The software controls the LED brightness and color. Automatic or manual operation are supported. If desired, settings for conditions such as brightness, intensity and LED color selection can be defined. We offer multiple color choices and the ability to operate in flash mode.

Fiducial Mark Recognition

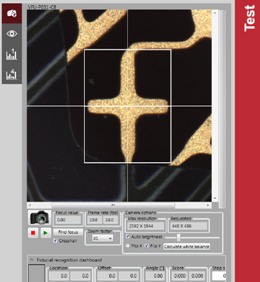

Capability for accurate positioning

For fully automated tests, a fiducial mark system can be ordered as part of our image capture system. This capability allows for accurate positioning of tools prior to the start of an automated test sequence.

In automation mode, the software scans for fiducial marks. After identifying their X-Y coordinates, the Sigma can begin a fully automated test sequence. Our software can import CAD data or it can be taught by teach and repeat.

The frame grabber camera function allows the operator to capture images before and after a test sequence.