We are making available more test type descriptions via our website. Today we give you more information about spring rigidity testing.

- Fast and easy operation

- Multiple force ranges

- High repeat frequency

- Auxiliary inputs to plot electrical characteristics against mechanical input

- All xyztec sensors work in two directions

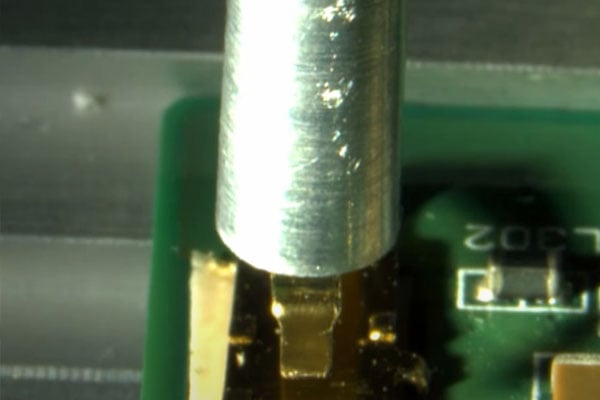

Spring rigidity test

There are many types of electrical spring contact, for example sliding contacts like those in connectors and switches and surface pressure contacts such as battery terminals and power distribution. The size, contact force, number of contact cycles and materials used varying depending on the application.

The performance of such contacts depends on characteristics like stiffness, deformation, material, moving mass and geometry. This can be analysed simply with the application of Hooke’s law, or more complexly where dynamic effects such as the contacts sliding friction, force profile, damping constant or clamp force are investigated against time and distance.

For example material properties like Young’s modulus might be measured:

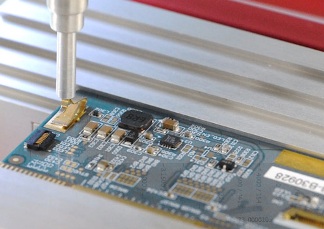

Xyztec has many tests that can investigate and measure the static, dynamic and life performance of your spring contacts with contact forces from a few grams force up to hundreds of kilograms. In cases like button switches and circuit breakers a push-pull test can evaluate force versus time and distance as single or multiple events.

Full control over test parameters

Our software offers full control over the test parameters including force, speed, distance and number of repeats. Data output can be in both numerical and graphical form, allowing full and varied analysis. The analysis can be performed either within the xyztec software or externally, using our comprehensive data exporting capability.

Auxiliary inputs and outputs

Our test platforms have auxiliary inputs for external sensors that might, for example, measure a failure of some kind that stops the test and records the number of cycles to the event. Auxiliary inputs enable in-situ testing to measure contact properties such as resistance in real time and synchronously with mechanical inputs of position and force.