There are plenty of reasons why all of the world’s top 4 semiconductor packaging houses have purchased a Sigma W12 for their 12-inch wafer testing requirements, during the past few months. In this newsletter we highlight a few key features of this market leading bond tester. Most commonly the W12 is used for precision shear testing, Cold Bump Pull (CBP) and big bump removal to prepare for wafer probing.

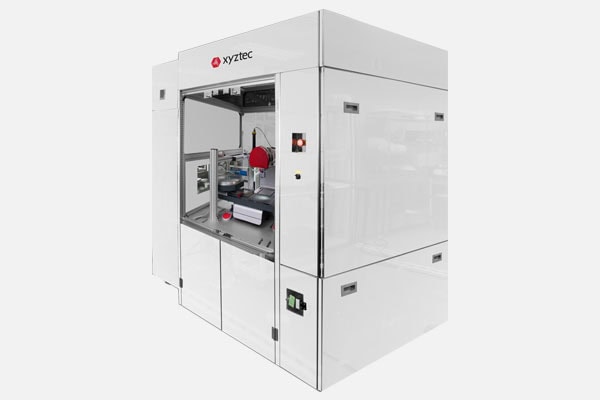

Integration transforms the bond tester into a fully automated system

Together with the market leaders of wafer handling equipment we offer a fully integrated and automated solution. We offer leading edge products for up to 300mm equipment frontend module (EFEM) platforms. The Sigma W12 features automatic wafer size detection, PID controlled centered lift pins for guaranteed secure wafer loading and un-loading.

In most cases the high air flow of xyztec vacuum chucks easily pulls down warped wafers. In cases of extreme warpage an optional wafer pusher ensures precise clamping. To make sure no debris is on the wafer or on the chuck a special cleaner is offered to perform fully automated pre- and post test cleaning.

Wafer map

The Sigma software offers import- and export of multiple file formats for wafer maps (KLARF, INF, etc.). After the import the map shows a complete overview. The system will guide you step by step through all marked defects.

The tested positions are clearly marked on the map. When all tests are finished, the wafer map and test results can be exported for full traceability. For each die a high resolution picture can be made that shows and marks the tested bumps. An offline viewer is available to check the exported wafer map files and the test results.

Market leader

As market leader in bondtesting in Europe and Taiwan, xyztec has produced lots of success stories since the company was incorporated in 2000. Click here for references. If you are interested in a live demonstration of the Sigma on your sample or perhaps for more bond testing inspiration, contact us today!

Watch bond testing being automated

Click here to watch our automation video or here to watch the video of the contactless cavity cleaner.