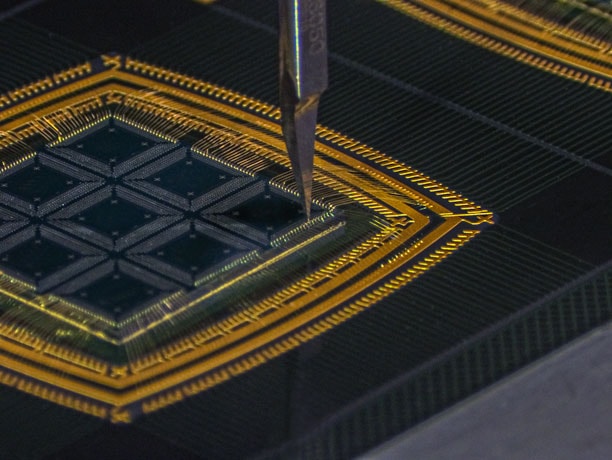

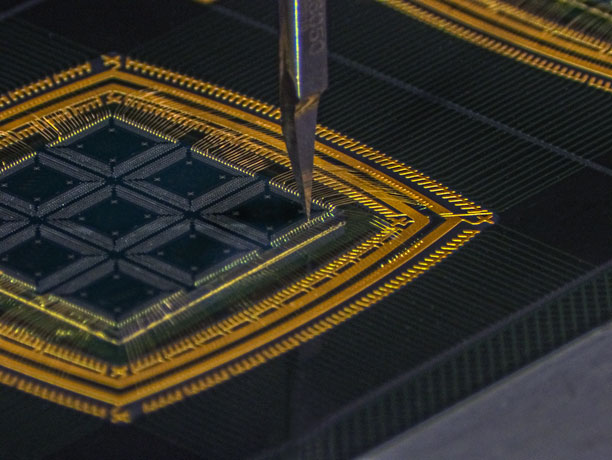

To provide end-users with an increasingly better product that is also reliable, bond test equipment requires accuracy in the micron range. The technology evolves, and assembly methods of bonding processes – dimensions of balls, wires, and pitches change. This challenges us as the frontrunner in bond testing to develop higher accurate bond testers for precise measurement data for statistical analyses.

Our Sigma bond testers can take positional accuracy to a new level with our latest improvements on table mapping in combination with high-resolution linear encoders and intelligent software.

Table mapping increases positional accuracy

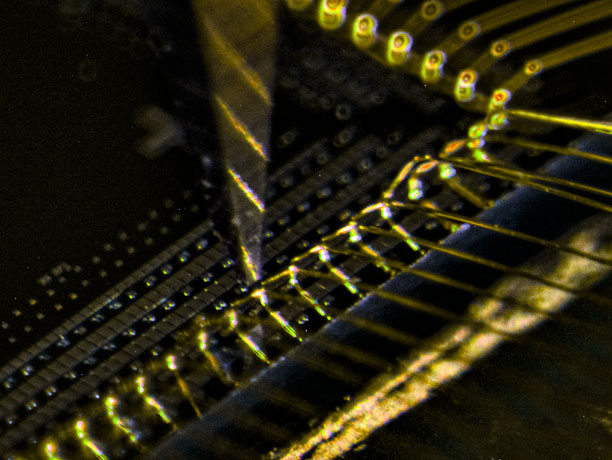

Table mapping opens up the possibility for you to test the interconnection strength of semiconductors that were previously not testable. Especially not automatically. Our experts employ advanced visualization techniques and software procedures to map the Sigma bond testers’ XYZ tables accurately. This unique technology enables the tester to compensate for even the slightest imperfections in movement at all positions of the stages.

Utilizing table mapping, we have made possible pull and shear, destructive and non-destructive, test solutions for wire and ball diameters down in the range of < 15 micron and pitches of < 5 micron.

Obtain and maintain accuracy

All Sigma bond testing systems are custom-made and guarantee high positional accuracy. The bond testers are adaptable for current and future market requirements, and we also offer on-site calibration to sustain and perform high positional accuracy.

We are already developing the next generation accuracy for Sigma bond testers in close cooperation with industry-leading partners. Developing by building on proven technologies, xyztec always offers market-leading functionalities and bond testers with unparalleled precision. Curious about what we can do for you? Contact us!

Auto grading without any assistance

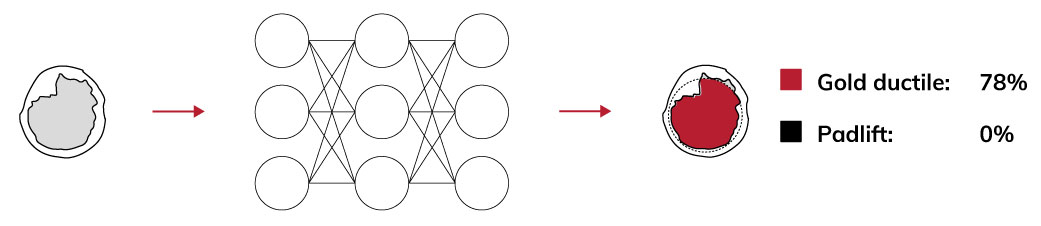

Another exceptional, unique development of xyztec is automatic grading. This makes fully automatic analysis without operator intervention possible and is one step forward in realizing 100% automated bond testing. Autograding uses machine vision software to process the images of the test results.

The algorithm uses a neural network, also referred to as deep learning. A Sigma can automatically determine the failure modes on samples, removing the need for operator grading on your parts. Imagine the endless possibilities!