We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorized as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site. ...

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

No cookies to display.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.

No cookies to display.

Advertisement cookies are used to provide visitors with customized advertisements based on the pages you visited previously and to analyze the effectiveness of the ad campaigns.

No cookies to display.

High-speed bond testing maximizes your units per hour (UPH) significantly. The standard Sigma* comes with a high axis speed of 50 mm/s, a direct-drive motor, and mapped linear positional encoders to ensure very accurate positioning.

Many systems rely on rotary encoders fixed to their drive motors. This system does an adequate job of positioning the motor. Backlash and hysteresis in gearboxes, lead screws, and linear guides induce very significant systematic errors of ±50 µm.

*Floor-based Sigmas come with high-speed axis of 500 mm/s and 10 nm encoders.

A controlled study with experienced users shows that the throughput of a Sigma compared to the most competing system is up to 39% faster.

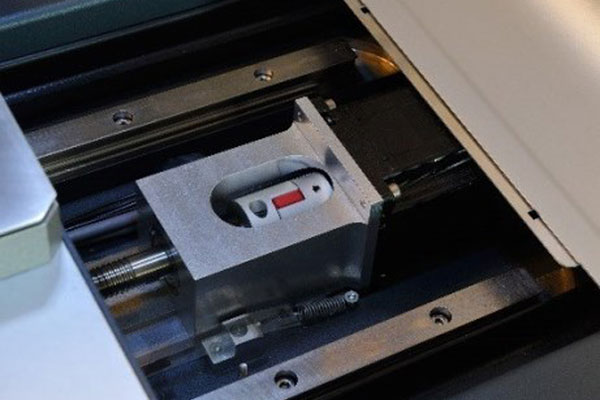

Testing the bond without any movement of the sample is essential for obtaining reliable, reproducible measurements. The fiducial pattern recognition capability combined with precision XYZ stages, consistently maintains initial tool alignment to within ±5 µm within the entire test volume with 0.5 µm repeatability. Our wide range of standard and customized work holders allows precise sample clamping with a system stiffness of 1 µm/10 kg.

Exchangeable work holders allow rapid production setup for all samples. If a work holder is not suitable for your sample, the quick release handle enables you to take off the work holder in seconds. This interface provides a secure lock capable of withstanding 200 kgf while maintaining reproducible positioning.

To keep the sample locked in position, a vacuum and/or clamping system is most common for low force measurements or flexible substrates. When testing higher forces, you can rely not only on our dedicated selection of standard work holders but also on custom designs for perfect sample clamping.

Versatile clamper with stepped jaws for stiff (non-bending) samples with widths up to 105 mm. 1 Knob controls both sides.

Versatile clamper with stepped jaws for stiff (non-bending) samples with widths up to 105 mm. Independent knobs control 1 side each.

Optional to the universal work holder are extended stepped jaws for samples with widths up to 186 mm.

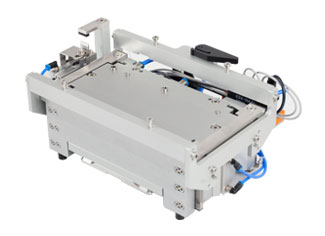

Ideal work holder for automatic bond testing. Combine the window clamper with a customized mask and inlay. Commonly used for lead frame applications with widths up to 70 mm. Vacuum optional.

Vacuum work holder for 2” – 8” wafers applications.

Easily clamp a wide range of sample shapes with the clamper pins.

Available in different sizes, can be mounted on standard interfaces and optionally inside universal work holders

Heating block (100×100 mm) for up to 500°C to equip with various customized inlays and external PID temperature controller. Optional with vacuum.

Clamper with a parallel movement of the stepped jaws to bend samples (3-points). Also available for 4-point bending.

Standard with a probe radius of 1 mm.

Jaws and bending radius are customizable.

Work holder XWV690068

Work holder XWC690428

Work holder XWU690079

Work holder XWC690432

Work holder XWC690431-battery

Work holder for lead frames

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Am Haupttor / Bürocenter

06237

Leuna

Germany

27182 Burbank

Foothill Ranch

CA 92610

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands