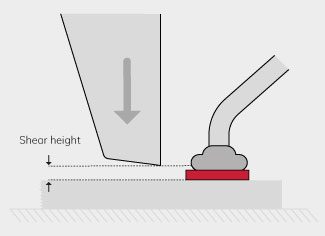

The shear height is one of the most challenging alignments to control on a bond tester. Variations between tests can influence measurements and make test results less reliable. The revolutionary nano control shear sensor solves all these issues by incorporating a unique drive within the shear sensor body with a closed control loop.

The sensor compensates any variation in shear height during the test and makes shear height during bond tests fully traceable. It is an exceptional solution to test accurate applications such as wafer-level, coating, and lead frames.

The patented nano control shear sensor consistently positions within 200 nm of the programmed shear height and maintains this alignment during the test. The sensor compensates for any variation in shear height during the test by using an internal drive with a closed control loop. The move to the shear height is also faster than traditional methods that involve clamping and other steps, increasing the number of tests per hour of the Sigma bond tester over other systems.

Another difficult-to-control aspect of shear height control is the landing force. All Sigma shear sensors include a vertical force sensor that provides its unique programmable landing force feature. No other bond tester can achieve landing forces down to 5 gf.

Maximize the number of tests per hour using the revolutionary nano control shear sensor. The move to the shear height of this shear sensor is faster than traditional shear sensors.

The Sigma was already the fastest bond tester on the market. As proven in a study with experienced users, the throughput of a Sigma compared to the most competing system is up to 39% faster. The nano control shear sensor significantly maximizes the units per hour (UPH).

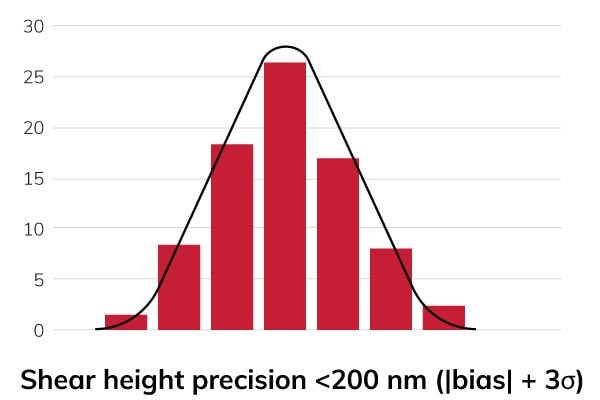

The measurement report below shows a reproducibility far below the specified 200 nm. For the investigation, 20 pads were sheared off at a programmed shear height of 2.3 µm. A Bruker white light interferometer measured the actual height of the sheared pads. The standard deviation on the shear height was only 35 nm. The nano control shear sensor’s stability sets a new revolutionary standard in the industry.

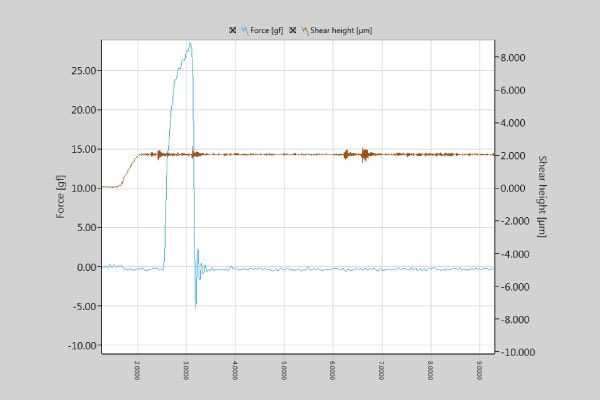

In addition to achieving and maintaining this unprecedented precision in shear height, the Sigma bondtester also records the shear height during the test. The measured shear height can be displayed in the force graph on a secondary vertical axis and is therefore for the first time traceable.

The nano control shear sensor, combined with a Sigma bond tester and a sophisticated work holder, enables performing bond tests previously deemed impossible and greatly enhances the meaningfulness of other existing tests. This is especially true for most wafer-level tests, coating tests, and tests on lead frame applications.

Dirk Schade