In the world of materials science, testing the intrinsic strength of brittle materials like ceramics, glass, and semiconductor wafers is paramount. Today, we delve into the intricacies of a powerful testing method that has revolutionized how we evaluate biaxial strength and axially symmetric bending: the Ball-on-Ring (BoR) test.

What is the Ball-on-Ring Test Method?

The ball-on-ring test method is a crucial technique widely employed for characterizing the biaxial strength and axially symmetric bending of brittle materials such as ceramics, glass, and semiconductor wafers.

Unlike traditional 3-point and 4-point bending tests, which might be overly sensitive to edge flaws and surface imperfections induced during backgrinding, the BoR test offers a more accurate representation of real-world application scenarios, as they seldom involve uniaxial stress. Axially symmetric bending demand less intricate sample preparation since the maximum tensile strength occurs at the center of the probe, away from the specimen’s edges.

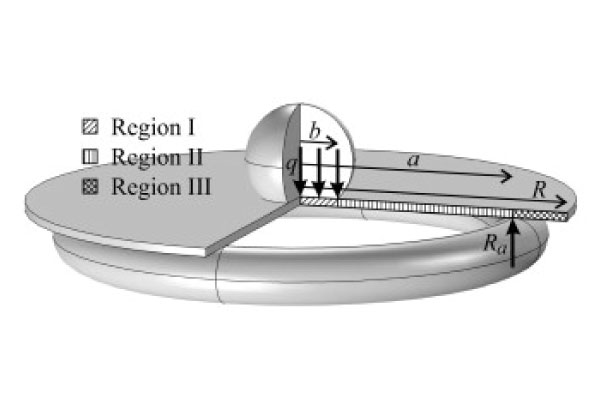

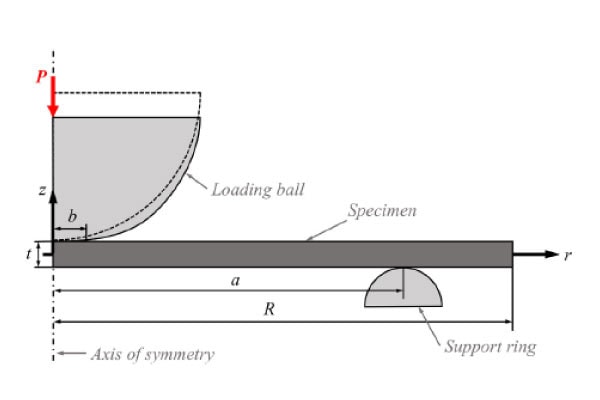

The images below show a 3D and a 2D schematic of BoR test performance.

How to Ball on Ring Test

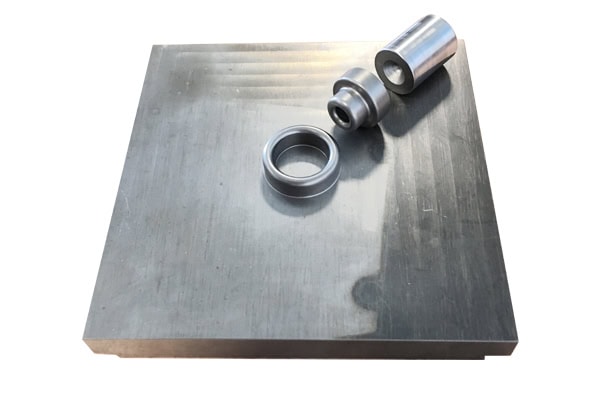

During a BoR test: a ring-supported specimen, typically a disc, is loaded with a ball positioned at its center. The maximal tensile strength in both radial and tangential directions is generally observed at the bottom of the surface in the center of the round-shaped plate.

Determining the maximum stress and effectively tested volume is crucial before assessing the strength of the tested specimen and transferring it to results obtained from other test methods.

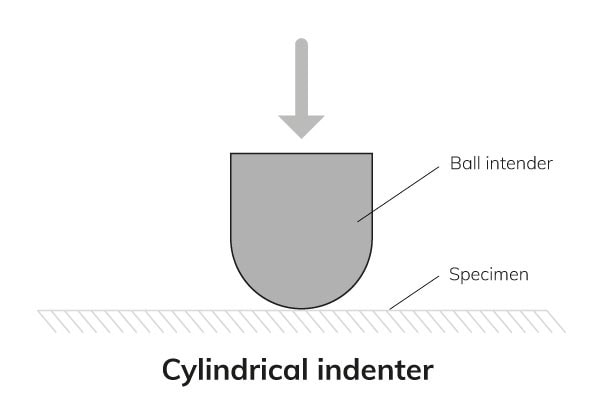

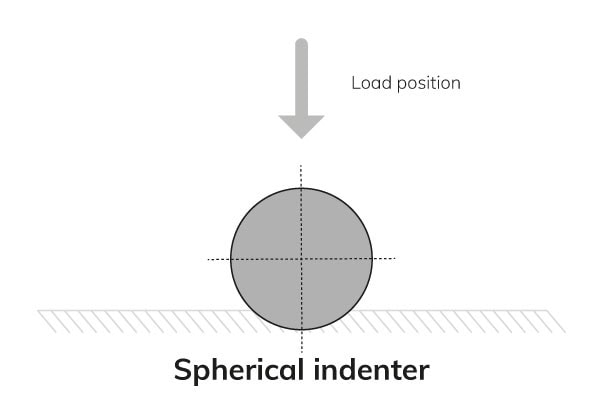

The geometry of the indenter and the support conditions dictate the stress field applied to the probe. While support conditions generally alter the overall shape or symmetry of the stress field, the geometry of the indenters significantly influences the maximum stress by defining the shape of the load distribution. Common indenter geometries include spherical shapes or cylindrical pistons. Cylindrical indenters are preferred over spherical ones when an arbitrary and/or load-independent contact radius with the specimen is desired.

Push Test Methods

The BoR stands among the array of Push Test types in which Sigma bond testers excel. A push (reverse pull) test epitomizes a method wherein the primary objective is to exert a downward load onto a sample, gauging its response against the applied force. This load can be either destructive, leading to part failure, or non-destructive, aiming at a force threshold. Force application may occur once or cyclically in non-destructive evaluations, unveiling part performance across repeated loading cycles.

Besides the BoR test method, our website is a treasure trove of insights on various test types, such as Bending, Connector Push, and Keypad push tests. Understanding such methodologies becomes increasingly vital as we continue to push the boundaries of materials science. Dive into bond testing and unlock new horizons in material analysis.