High-resolution cameras and flexible LED illumination are a must-have to achieve robust automation processes. We offer different cameras, adjustable LED illumination, and fantastic image processing options to bring out the features of interest and automatically correct many bond position variations.

In this newsletter you can read all about the camera options and vision functionalities xyztec offers to support high-resolution image processing, best-in-class tool position management, feature recognition, and grading. Scroll down to the end of the newsletter and get your free SMT ticket for the SMTconnect 2022 in Germany from 10-12th May.

High resolution cameras

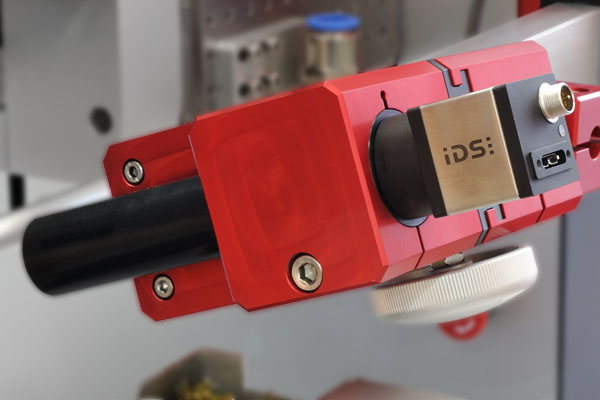

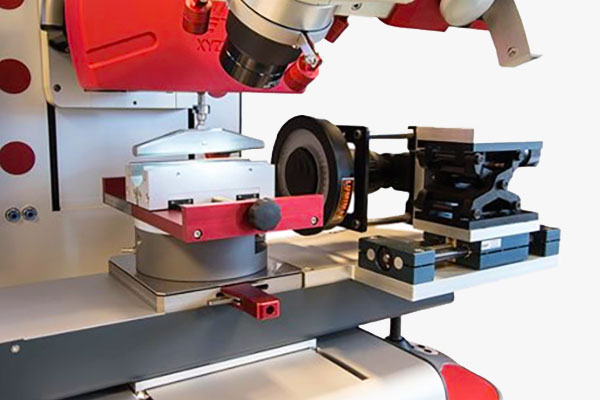

We offer 3 camera options with excellent vision functionalities for high-resolution image processing. If multiple magnifications are required, 2 rigidly mounted cameras provide better inherent accuracy than 1 camera with a zoom. To realize optimal tool alignment, we offer a camera in the trinocular microscope for live video imaging and/or a side-view camera to provide a different point of view.

|

|

|

Downward looking camera |

Trinocular (microscope) camera |

Side view camera

|

|

|

|

Downward looking camera

A Sigma bondtester comes with a build-in perpendicular downward looking camera on one side of the Measurement Unit. An extra downward looking camera on the other side is optional. Both cameras have vertical height adjustment and come with dome and coaxial lighting.

Choose between 2 magnifications (3x, 6x) in addition to a standard Large Field of View (LFOV) configuration:

| Magnifications | Field of view |

| 3x objective=400x | 2×2 mm field of view

2 µm optical resolution 30 µm depth of focus |

| 6x magnifications=800x | 1×1 mm field of view

1.5 µm optical resolution 20 µm depth of focus |

The downward looking camera is great for image capturing, position recognitions of fiducials and wires, and failure mode analysis and grading.

Trinocular (microscope) camera

A trinocular microscope camera is perfect for live video and image capture. This is an excellent function for automation, teaching, and data capture for customer presentations.

Side-view camera

The side-view camera offers unique options to bring out the features of interest. For example, to provide a different point of view to provide optimal alignment, fiducial recognition and auto grading.

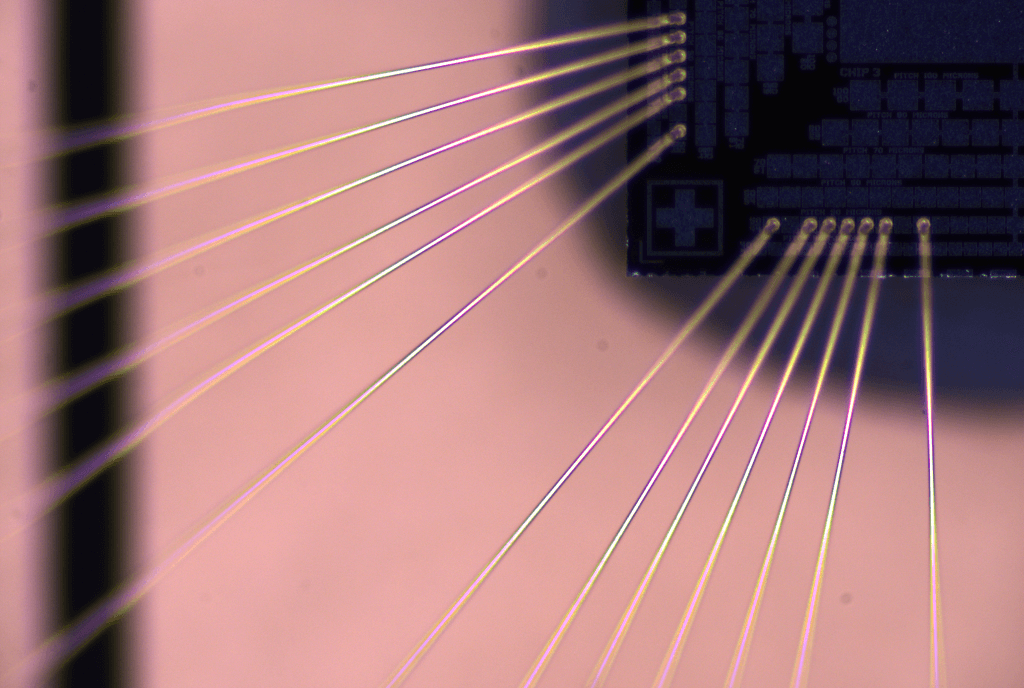

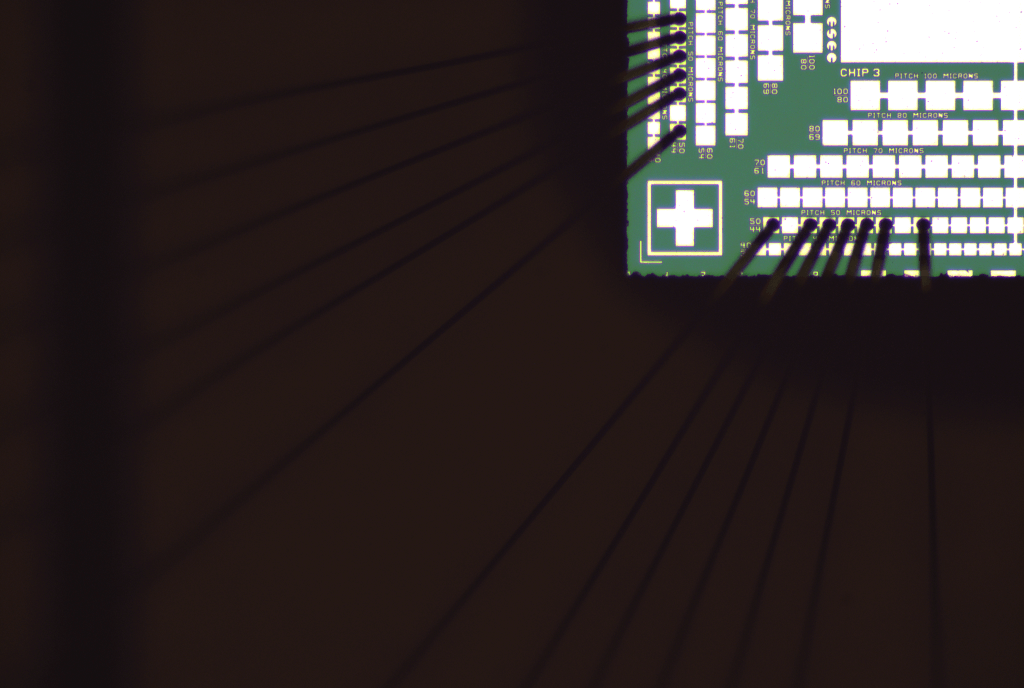

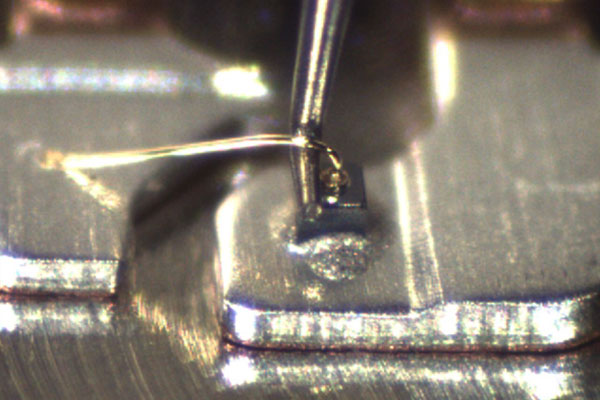

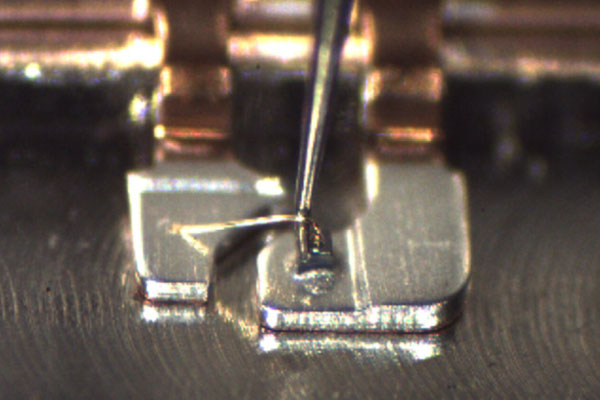

Different magnifications on samples

Downward looking camera3x objective=400x |

Trinocular (microscope) camera2592×1944 px resolution |

Side view

|

|

|

|

|

|

|

|

Illumination

In addition to camera optics, illumination plays a critical role in image analysis to achieve the right amount of contrast, for example. We offer types of illuminations: diffused and coaxial. It is possible to combine both types of illumination with independently variable intensities. The different illumination properties can then be selected or mixed to assist image analysis by increasing the contrast between the feature of interest and the other areas of the sample.

Diffused (bright field) illumination

The dome-shaped illumination generates diffuse lighting on the test object from all directions and achieves a completely shadow-free illumination.

Typical applications for dome illumination are the inspection of reflective or specular materials and complex or curved surfaces (like wires and ball-type features). Dome lighting is very well suited for standard-compliant reading and verification of two-dimensional codes.

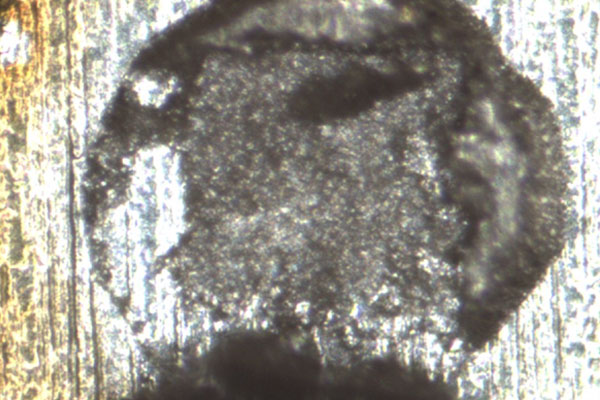

Coaxial (dark field) illumination

Coaxial lighting illuminates along the axis of the camera only. This technique is ideal for objects with flat reflective features (like fiducial marks), shiny surfaces with no or shallow profile, or surfaces with diffuse backgrounds.

Examples are the inspection of printed circuit boards, reflective stickers, polished silicon wafers, and print inspections.

In the below dark field example, many wires are made visible for easy camera programming of wire and bond positions. If the position of wires varies between samples, wire detection automatically corrects it for each test.

High-magnification cameras

Boost the standard downward looking camera performance with a high-magnification zoom lens for highly repeatable and automated precision optics and advanced light distribution.

- Optimization for the standard downward looking camera

- Higher resolution cameras (12MP/18MP)

- To combine with multiple standard lenses

Image processing

Control brightness, intensity, and color settings using machine vision software for advanced shape recognition. Easily store the images for failure analysis reporting, operator training, or customer presentations.

Custom camera solutions

With the ever-increasing complexity of modern circuits and the inherent reliability issues, it becomes necessary to adopt tools that minimize product risk. We also develop customer specific camera solutions to enhance material testing with a Sigma bond tester. When combining this camera with digital image recognition software, engineers have an additional tool to provide motion and strain analysis.

Vision enhanced material testing

Digital Image Correlation (DIC) is a non-destructive, optical field measurement method based on video image capturing and digital image processing by providing a 2D full-field result.

The 2D image software analysis motion, deformation, and surface changes. The software offers a considerable amount of flexibility, including:

- Motion analysis during an impact test

- Local deformations during a bend test

- Crack propagation at the interface of a compound material

Get your free SMT ticket!

Xyztec is exhibiting at the SMTconnect 2022 in Germany from 10-12th May, and we would like to invite you to our booth Hall 4A – Booth 147. Get your free SMT ticket by sending a short e-mail including your full name, telephone number, and company name. You will receive the corresponding code from us to register for the SMTconnect.