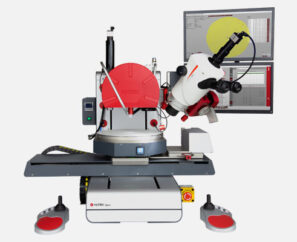

Today we would like to highlight the latest addition to the xyztec product family: the Sigma W12.

Sigma W12

Ideal solution for 300mm (12 inch) wafer testing

- Precision shear testing and Cold Bump Pull (CBP)

- Bump sizes down to 20µm

- Grading run functionality

- XY mapping coordinates key in function

- Easy positioning, alignment

- High resolution cameras with high and low magnifications

- Fastest throughput of wafer bump testing in the world

- 500mm X-stage and 370mm Y-stage, throat depth 400mm

- Integrated report editor and flexible data export

- Reach 100% of the 300mm wafer without repositioning the wafer on the chuck

- Blower and vacuum tool cleaning unit

- Wafer chuck with safety interlocks and 360 degree rotation

- Wafer carrier mechanically locked when vacuum is turned on

- Complies with JEDEC JESD22-B117A, JEDEC JESD22-B115 and JEITA EIAJ ET-7407 standards

- Also suitable for 200mm (8 inch) and other wafer sizes

- 24 bit ADC resolution, 10kHz sampling frequency

- Compatible with Revolving Measurement Unit (RMU) and single heads

- Unparallelled 0.075% accuracy

The Sigma W12 is specifically designed for precision shear testing and Cold Bump Pull (CBP) on wafer or at wafer level. The system has the largest X/Y and fastest stages available in the industry, to reach all positions on the wafer with the tool and cameras in record speed. The 30nm resolution linear encoders ensure accurate positioning.

The Sigma automation features ensure rapid testing of randomly selected positions on the wafer. Fiducial mark recognition can guarantee a high repeatability. Cameras also assist the operator to perform grading. The grading run functionality enables quick grading after a sequence of tests.

Compatibility with the xyztec Revolving Measurement Unit (RMU) ensures that you can switch between test types and tools with the press of a button. Unused sensors (cartridges) are protected within the machine.

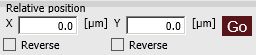

The XY mapping function enables the operator to quickly and accurately move from position to position on the wafer by keying in a relative move. Naturally, the Sigma W12 is equipped with 30nm resolution linear encoders, ensuring 0,5µm repeatability.