At Xyztec, we always look for ways to enhance your manufacturing processes. Our Sigma bond testers are now fully GEM300 compliant, offering you an opportunity to achieve seamless communication and unparalleled efficiency for fully automatic lead frame testing or wafer testing.

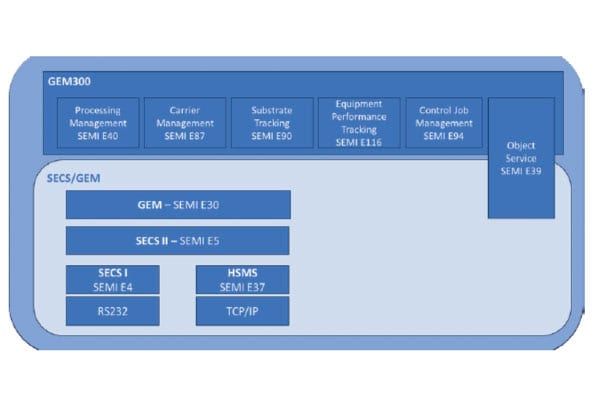

What is GEM300?

GEM300 is a game-changer in the manufacturing world. It is an unstoppable force transforming the manufacturing landscape. While SECS/GEM standards serve factories with minimal automation, the high-end production environment demands more. With automated material transport via AGV or OHT and other advanced systems, the GEM300 standards become the gold standard.

Seamless Communication:

GEM300 facilitates seamless communication between your bond tester and manufacturing equipment. Imagine a production line where every system speaks the same language, ensuring a smooth and efficient workflow.

Fully Automated Bond Testing:

GEM300 isn’t just about talking the talk; it’s about walking the walk. With GEM300 compliance, you can achieve fully automated bond testing. This means less manual intervention, reduced human error, and higher productivity.

Streamlined Data Exchange:

When your bond testers are GEM300 compliant, exchange headaches are a thing of the past. Enjoy streamlined data transfer, analysis, and reporting, leading to faster decision-making and improved quality control.

Interoperability:

GEM300 isn’t limited to a single manufacturer or technology. It’s an industry-wide standard that fosters interoperability, allowing you to choose the equipment and tools that best suit your needs.

GEM300 comprises

- Carrier Management (SEMI E84 + E87): Handles material delivery, validation, and transfer via AGV or OHT. The bond tester validates ID and Slot map using readers and sensors.

- Substrate Tracking (SEMI E90): Monitors substrate movement with built-in readers for ID verification.

- Process & Control Jobs (SEMI E40+E94): Process Jobs list materials and process recipes; Control Jobs manage sets of Process Jobs.

- Equipment Performance Tracking (SEMI E116): Analyzes performance for preventive maintenance, minimizing downtime, and anticipating alarm causes.

Experience GEM300 for automatic lead frame and wafer testing

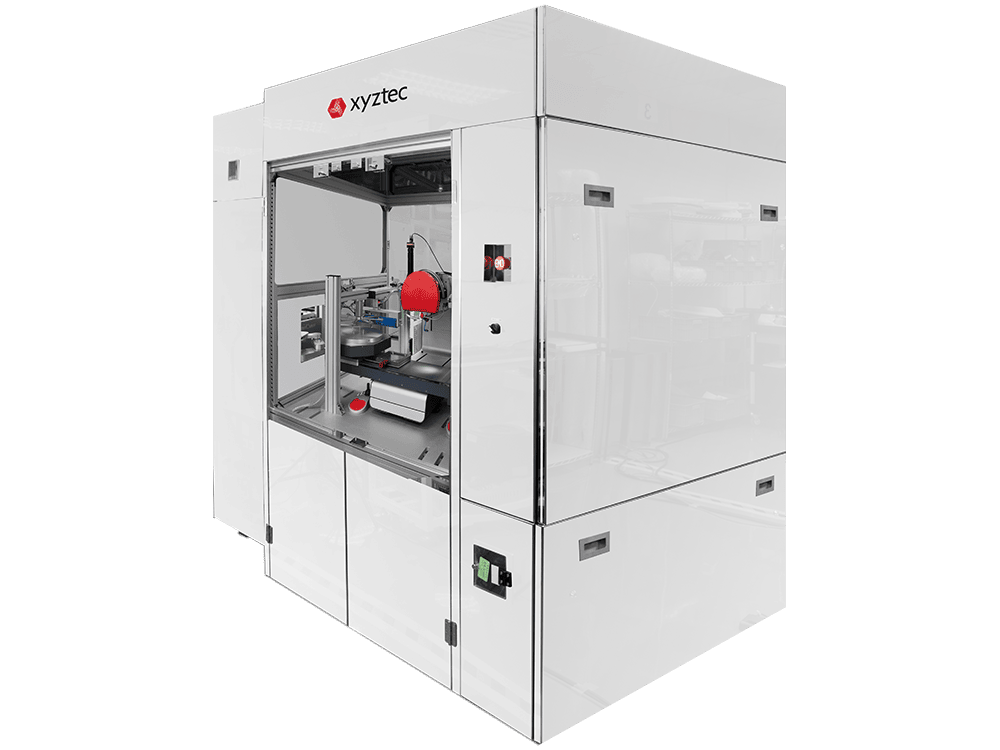

We proudly announce that Sigma bond testers are now fully GEM300 compliant. This compliance is especially valuable for fully automatic lead frame testing or automatic wafer testing.

Sigma MAG Magazine Handler with GEM300

Our Sigma MAG magazine handler with Loadport is the ultimate solution for seamless, operator-free (un)loading of magazines. It communicates effortlessly via SEMI E84, offering versatile top- and frontloading options through Overhead Transport (OHT), Automated Guided Vehicle (AGV), or manual operation.

Safety is our top priority, as the Loadport features a protective enclosure for automatic bond testing, ensuring compliance with safety and ergonomic standards (CE certification) in accordance with SEMI S2/S8.

Sigma W12 wafer tester with GEM300

Experience the Sigma W12 wafer tester empowered by GEM300 integration. Watch as your bond tester evolves into a fully automated system, streamlining your operations for unmatched efficiency. With GEM300, communication between your bond tester and manufacturing equipment flows seamlessly, ensuring a harmonious production process.

We are at the forefront of tackling bond testing challenges and proactively anticipating future demands. Our commitment is to craft customized solutions that meet and exceed all test requirements and comply with SEMI standards.

Take the leap into the future

Your success is our priority, and we’re here to help you achieve it. Join us on the path to innovation, efficiency, and excellence in bond testing with GEM300 compliance on your Sigma bond tester. Contact our experts today and take the leap into the future.