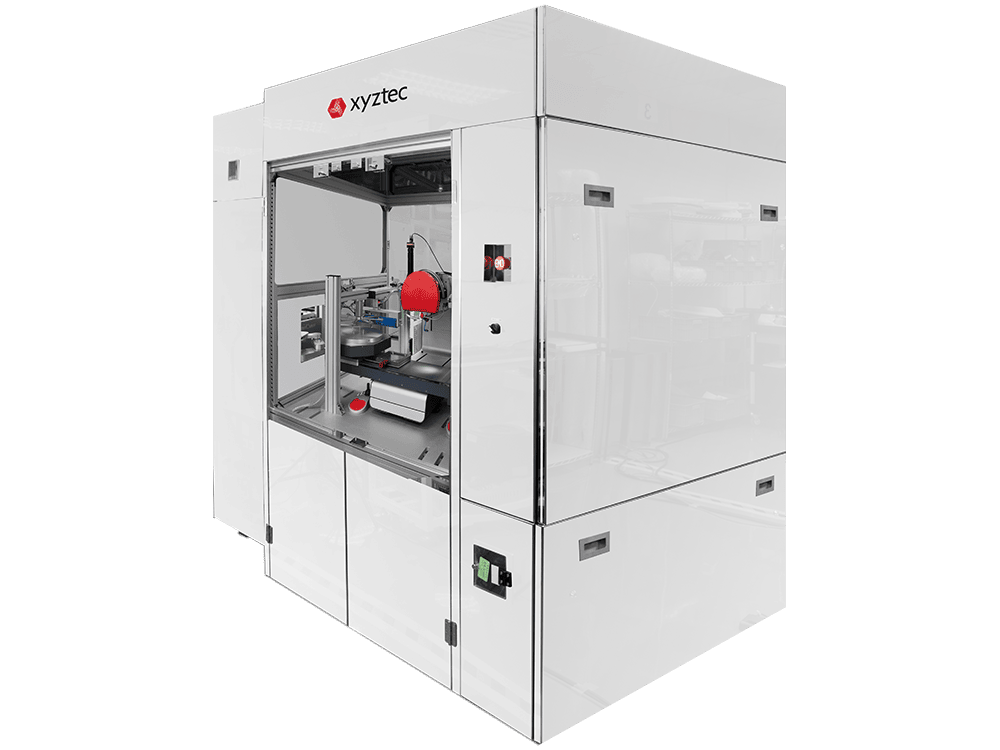

In 2025, xyztec proudly celebrates 25 years of innovation and pushing the boundaries in bond testing technology. Over the past quarter-century, we have been committed to advancing precision, efficiency, and reliability, setting industry benchmarks.

From the redevelopment of the Megabond design and the Revolving Measurement Unit (RMU) to the groundbreaking Sigma Nano shear sensor and next-genaration Sigma Serie Bond Testers, every milestone in our journey reflects our unwavering commitment to innovation and customer satisfaction.

Let us journey through the key milestones that have defined xyztec’s legacy and continue to shape the future of bond testing.

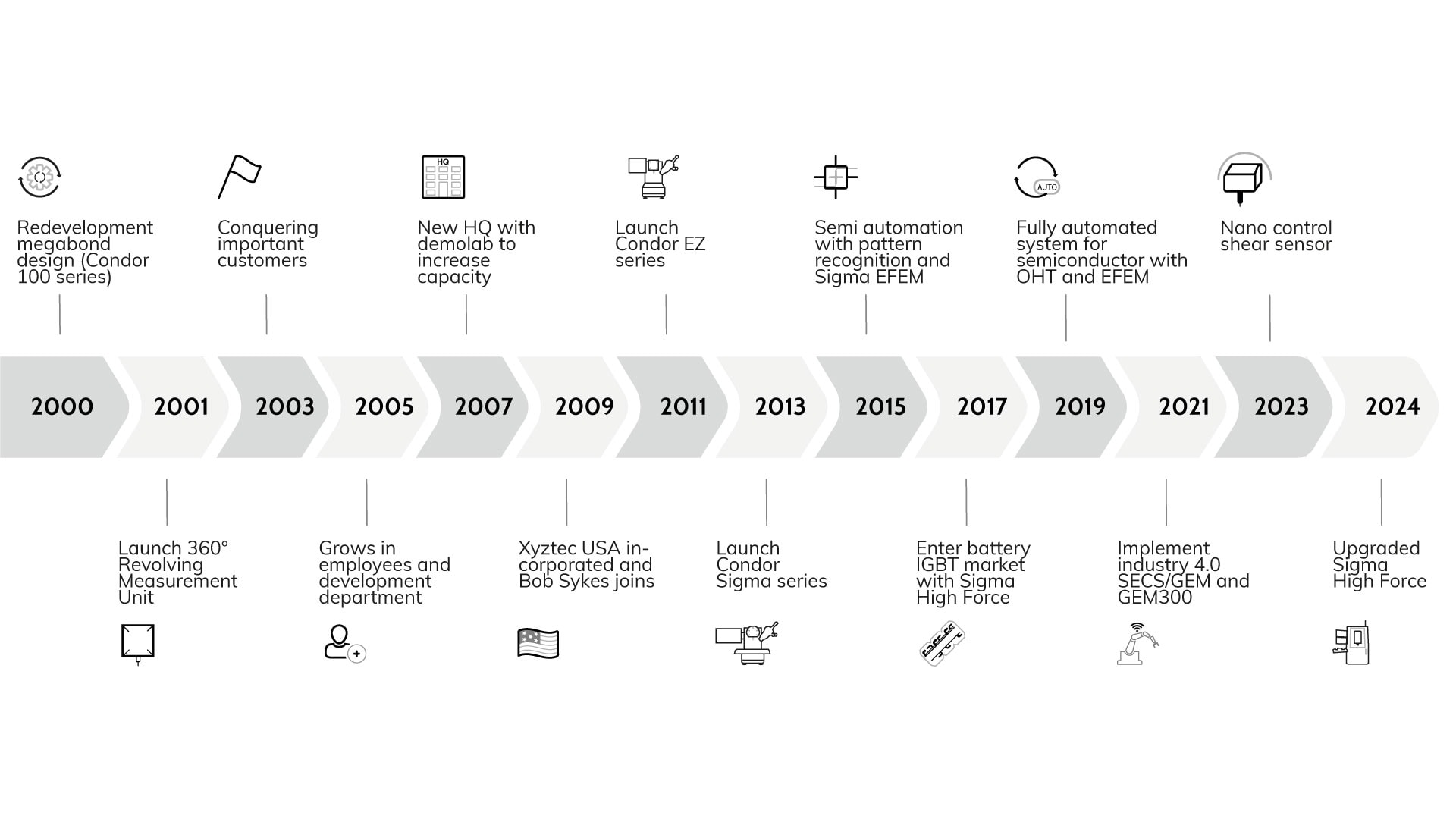

2000: Redevelopment of the Megabond design

We began the millennium with the launch of the Condor 100 Series, which introduced multifunctionality in bond testing. Key features included the Revolving Measurement Unit (RMU) for up to four sensors (supporting loads up to 40 kgf), a Dimmable Cold Light Source, and XY stage options ranging from 70 mm to 250 mm.

2001: The Game-Changing Revolving Measurement Unit (RMU)

The introduction of the Revolving Measurement Unit (RMU) revolutionized bond testing flexibility. With the capacity to handle up to 40 kgf across four pull or shear test sensors, it offered unmatched versatility. The addition of software-controlled electrical tweezers and dimmable lighting further enhanced precision and usability, making it a standout innovation in the industry.

2008: 150 High Force Bond Tester

Additionally, the 150 HF bond tester, offering unparalleled precision and stability with a rigid support base, high-force linear guides, and safety measures. With a 360° rotation feature for automated shear tests, complemented by an optional Z-stage capable of handling push/pull forces up to 500 kgf.

2011: The Evolution Continues with the Condor EZ Series

The launch of the Condor EZ Series marked another leap forward. Designed for faster setups and optimized operations, it featured:

- Ergonomic microscopes for seamless sample handling.

- EZ joysticks for intuitive control.

- Open software for better navigation and connectivity.

With optional Impact Measurement Units and tailored designs for high-force applications, the EZ Series broadened testing capabilities significantly.

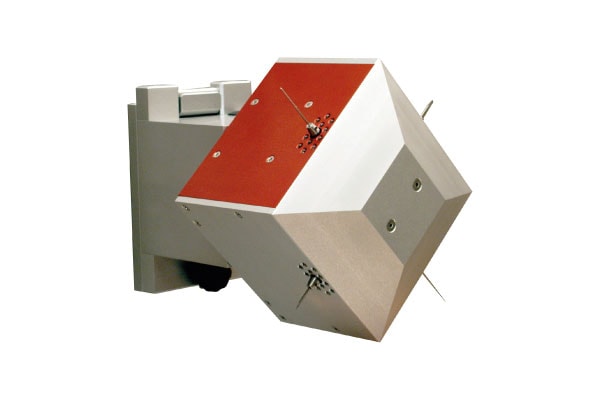

2013: Introducing the Condor Sigma Series Bond Testers

The Sigma Series was a milestone in automated bond testing. It became the industry standard, combining precision, flexibility, and groundbreaking automation. The Sigma Series redefined efficiency and accuracy with an upgraded RMU supporting up to six sensors and 200 kgf force capacity. Today our Sigma series includes:

- Sigma: The most advanced bond tester with game-changing automation capabilities.

- Sigma Lite: Affordable ownership with high performance and scalability.

- Sigma W8: Automatic bond tester for 4” – 8” wafers (up to 200 mm).

- Sigma W12: Fully automatic tester for 2” – 12” wafers (up to 300 mm).

- Sigma MAG: Magazine handler for hands-free lead frame testing.

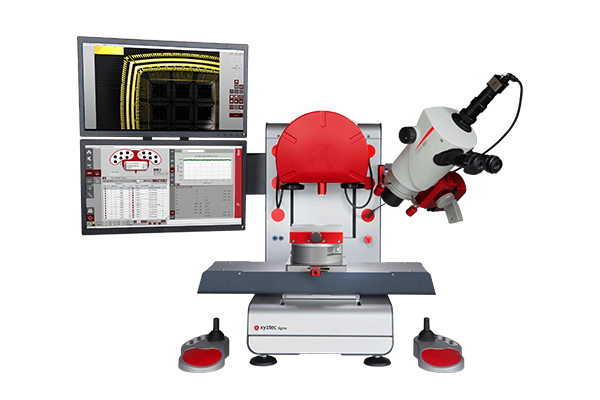

2015: Launch Condor Sigma EFEM

Automation reached new heights with the Equipment Front End Module (EFEM). Designed for operator-free testing, it supported wafers up to 12” and introduced capabilities like Cold Bump Pull testing. The Sigma EFEM’s precision and reliability made it an essential solution for high-throughput environments.

2017: The powerful Sigma High Force (HF)

The Sigma High Force (HF) bond tester delivered unmatched power, capable of testing forces up to 1000 kgf. It is specifically designed for industries like power modules and battery testing. Its 360° head design, multiple camera options, and deep access capabilities made it the ultimate tool for demanding applications.

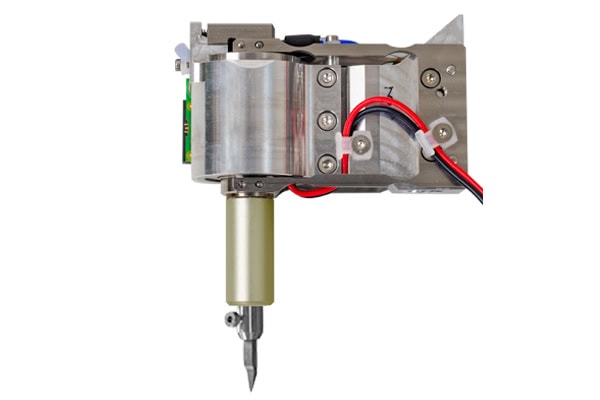

2023: The Nano Control Shear Height Sensor

Precision peaked with the Nano Control Shear Sensor, a patented innovation that addresses shear height variations. A precision of 200 nm (bias + 3σ) allows for swift adjustments to shear height, guaranteeing accuracy even in the most demanding applications such as wafer-level, coating, and lead frames. This sensor boasts a force sensor accuracy of ± 0.075%, ensuring reliable measurements with every test. It is compatible across all Sigma systems and sets the benchmark for wafer-level, coating, and lead frame testing accuracy.

2024: Enhanced Sigma Bond Testers

We introduced significant upgrades across the Sigma product line. These enhancements included better positional precision, unparalleled measurement accuracy, and increased higher throughput (UPH) speed.

2024: Next-Generation Sigma HF

We also unveiled the revamped Sigma HF, setting a new benchmark for high-force, large-area bond testing. With a stable granite platform, updated PLC software, and an innovative design, the Sigma HF is already proving its worth in demanding industries worldwide.

Join the Future of Bond Testing with Sigma Bond Testers

Over the past 25 years, every innovation at xyztec has been driven by our commitment to excellence and customer satisfaction. Our Sigma Bond Testers stand as a testament to this dedication, offering:

- Unmatched Precision: Delivering superior accuracy in shear height control and force measurement.

- Game-changing Automation: Equipping your processes with cutting-edge features to maximize efficiency and throughput.

- Versatility and Flexibility: Adapting seamlessly to diverse testing needs, from the compact Sigma Lite to the robust Sigma HF.

- Cost-Effective Solutions: Combining high performance with a low cost of ownership for an unbeatable return on investment.

As we celebrate 25 years of innovation, we remain focused on pushing the boundaries of bond testing technology. Let us help you achieve your goals with confidence, precision, and reliability.

Contact us today to learn how our Sigma Bond Testers can redefine your testing processes and elevate your standards for quality and performance.