Wire detect

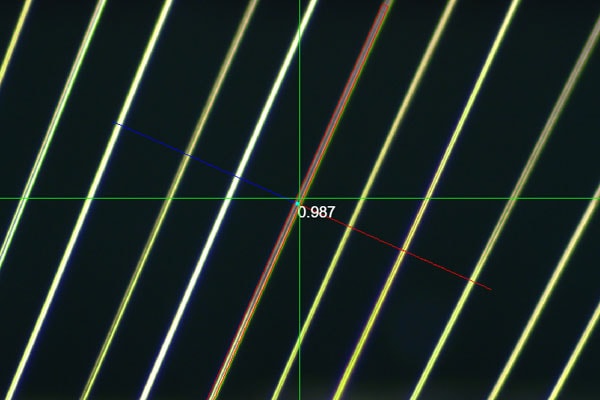

As more and more companies are making the transition to automatic wire pull testing, the engineers are also finding out its limitations. On many products, the placement of wires is not consistent and simple automation programs will miss the wire or pull two wires at once. Xyztec’s Sigma is the only bond tester in the world to overcome this problem with its automatic wire detect functionality.

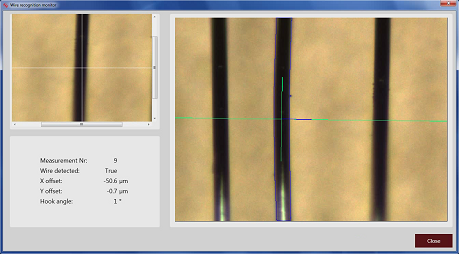

Control for production tolerances

The Sigma high-resolution cameras combined with advanced wire detect algorithms allow the bond tester to correct for production tolerances for every single wire and allow for automation, even with fine pitch wires. Additionally, the Sigma offers automatic and consistent positioning along the wire, which can be set up as a percentage between the first and second bond. Alternatively, the pull position may be calculated to produce any required angle at either the first or second bond and the forces at both bonds calculated. Missing wires or recognition problems can be handled during the automation cycle or after, via extensive reports.

Teach the position

The system is surprisingly easy to use, with a flexible AOI editor. Positions can be taught by means of the microscope (3D) and/or any of the three cameras that can be fitted on the Sigma. Wire detect is one of many image processing capabilities of the Sigma. The automatic wire detect function was introduced at Productronica in Germany and is most relevant to automotive customers, hybrids, LTC, COB, leadframes and strips with multiple wires.

Contact us to see what is possible on your samples.