Connector Push

Rigorous Connector Push Tests are conducted to assess the resilience and reliability of electromechanical connectors. These tests are essential for guaranteeing seamless electrical connections between subsystems, even in the face of external mechanical stresses.

Understanding the Connector Push test

Mechanical tests are pivotal for evaluating the durability of products subjected to external mechanical forces. During the Connector Push Test, components such as PCB terminals, connectors, and electronic housings undergo scrutiny for strength, deformation, bending, and breakage tendencies in conductor outputs and contact surfaces.

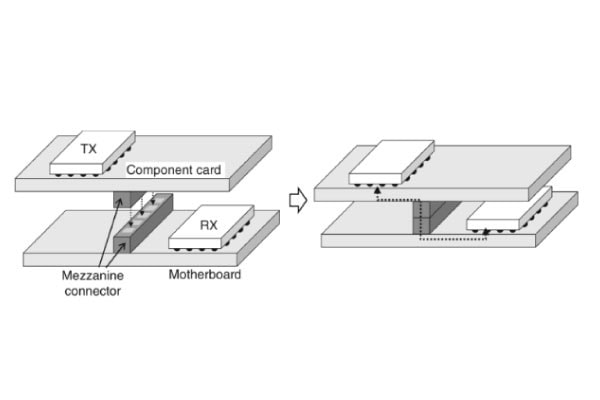

Figure 1: Parallel arrangement of a mezzanine connector, with TX as transmitter and RX as receiver

Electromechanical Systems

Connectors are electromechanical systems that provide separable electrical connections between two subsystems without signal distortion or power loss with the designed application and/or lifetime performance.

As the connectors’ structure is mechanical but its function is electrical, it has to be tested for its mechanical properties after a certain period or use cycles. Therefore, a defined force is applied to the stop parts to check the correct positioning inside the connector or verify that the connector is locked in position.

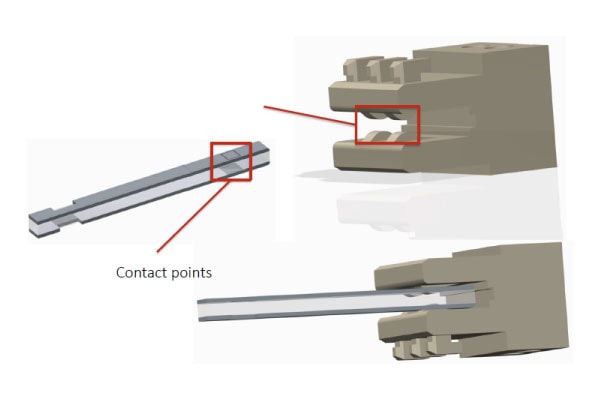

Figure 2: Connector with different levels for interconnection

Figure 3: PCB with plug

Critical Parameters

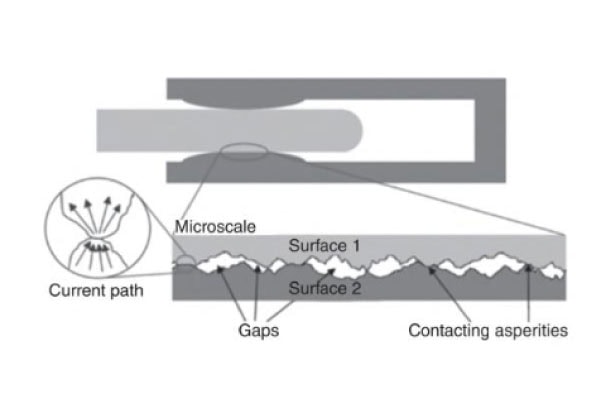

An important parameter for the reliability of a contact is the so-called contact normal force. To determine this value, the plug element of the connector is pressed vertically into the matching socket. The setting of a contact normal force within a defined window is an essential criterion for both the electrical and mechanical behavior of the connector, whereby high force values have a negative influence on the pluggability. However, if the force value is too low, achieving tolerable contact resistance with long-term stability may not be possible.

Figure 4: Cross section of a connector interface

Figure 5: Cross section of contact interface

Applications and Tools

Our Connector Push Tests cater to a wide array of electromechanical connectors, including TCP/IP, RS232, USB, HDMI, Parallel Port, IEEE488, CAN, I2C, and more. We utilize customized tools tailored to specific applications, ensuring precise and accurate testing protocols.

Reliability Assessment

The Connector Push Test is a definitive method to evaluate the reliability of connector pairs. The applied force to the system is precisely matched to the corresponding application. Seamless plugging and unplugging of connector pairs without compromising signal quality are paramount. This test remains the most effective and comprehensive means of determining the number of cycles a connector pair can endure before experiencing interruptions in electrical contact.

How to Connector Push test

Media error: Format(s) not supported or source(s) not found

Download File: https://xyztecvideos.b-cdn.net/Connector%20test.mp4?_=1