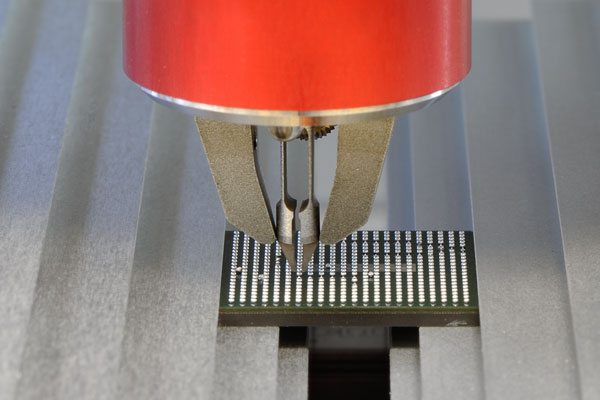

Tweezer pull

Tweezer pull is simply a pull test performed by a tweezer. During the test an upward force is applied to a wire, a ribbon or some other feature on your sample after being gripped by the tweezers. In many cases, the sample has to be prepared for testing first.

A peel test is essentially the same, but apart from an upward movement, the XY stage also does a controlled move. Normally, the purpose is to maintain a perpendicular force on the ribbon or wire being pulled off the substrate.

How to: Wire pull

We aim to spread knowledge about bond testing in the industry. That is why we have an extensive “how-to” on Tweezer Pull on our website.

Tweezer thin wire pull test

Media error: Format(s) not supported or source(s) not found

Download File: https://xyztecvideos.b-cdn.net/Tweezer%20pull%20test%20-%20thin%20wire.mp4?_=1Tweezers ribbon peel test

Media error: Format(s) not supported or source(s) not found

Download File: https://xyztecvideos.b-cdn.net/Tweezer%20peel%20test%20-%20ribbon.mp4?_=2

Tweezer features

- Measured force equals the applied force

- Very accurate test results

- Programmable and traceable opening position and closing force

- Programmable landing force

- Programmable force maintain

- The RMU can hold up to 6 sensors and/or tweezers

- Perfect solution for thin wire pull, ribbon peel, Cold Bump Pull (CBP) and many other applications

Pin pull test

Tweezer pull testing is comparable to standard pull testing. The difference between them is that special tweezers are used to clamp the part and hold it before pulling the part. Tweezer pull testing is used to perform pull tests on wires, ribbons, pins, balls or components. It is important that the part that is tested is not dislocated when the tweezer is closed.

For a standard wire pull test the hook applies the force by pulling the wire. The applied force on the wire is not equal to the force applied to the ball or wedge, because the force is not applied exactly above this ball or wedge. With a tweezer pull test it is possible to apply the force directly above the ball or wedge. The measured force will equal the applied force. Before performing this test, it may be necessary to cut the wires first. This can be done with special tips that can cut the wire. It is also possible to shear the bond on one side, straighten the wire with the tweezer and then perform the test.

Xyztec offers the USB tweezer as a general solution for most tweezer pull tests. The tips on this tweezer can be changed and the required force to clamp a part can be set in the software. We also offer special tips to cut a wire, and we have specialized tweezers for higher forces or very small parts.

CBP Jaw Cleaner

During use, solder builds up in the cavity in cold bump pull (CBP) jaws. This reduces their grip efficiency and affects the quality of your measurements. Cleaning the cavities is very difficult and small ball cavities can be damaged easily.

Advances in tweezer pull testing

Click here to read the article that was first published in Chip Scale Review May June 2014.

Micro drives with the ‘strength of a giant’

Click here to download an article by Faulhaber, called “Mechanical stress test for component solder joints and bonding wires – Micro drives with the ‘strength of a giant'” (PDF) on the USB Tweezers.