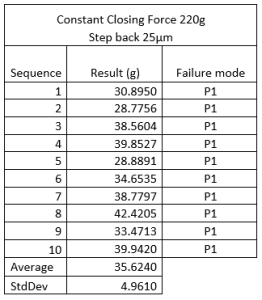

Copper pillar pull

Copper pillar is rapidly being adopted as a bumped wafer interconnect. The construction is that of a Copper cylinder around 50µm in diameter and height, topped with a dome of solder.

As with any interconnect the quality of the bonding process between the different parts is vital for the reliability of the finished product. The bond between the copper and its pad on the wafer are of particular interest as this is seen as the most likely failure mode. In a bond test a failure mode between the copper and wafer is then the “failure mode of interest”.

Test features

- Sensor accuracy ±0.075%

- Down to 35µm diameter copper pillars

Copper to pad interconnect

Pull testing

This failure mode can be produced by either a pull or a shear test and the measured bond strength used for your process control. In many other applications pull testing is typically preferred because the bond is subjected to a simple tensile load, distributed over the bond area. The bond separation is clean making failure mode analysis of the surfaces relatively easy. Unlike solder bumps, Copper is relatively hard and gripping it therefore easier.

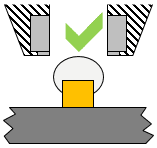

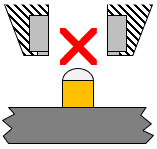

Solder balls require precise reforming in order to be able to apply a meaningful test load on to the bond. Copper also has to be reformed in order to be able to grip it but this takes the form of well know gripping methods such as plain surfaces and friction, a few serrations that slightly reform the copper in order to get a mechanical grip or a slight tapper.

Solder to copper interconnect

Cold bump pull testing

If you are interested in the interconnect between the solder and the copper, it depends on the shape of the construction whether a Cold Bump Pull (CBP) type test is feasible. If not, a shear may be the only effective test to qualify your process. More on CBP can be found in our how-to test bonds.

The test sequence for the CBP-approach is as follows

Choose between pull and shear testing

The choice between pull or shear testing depends on the application and the test objectives. Xyztec has a lot of experience with different types of copper pillar products and can advise you on how to test in order to get the best information for your quality assurance process. If you are interested to find out more please contact us for more information, to request an application report, a demonstration or a quotation.